GN-6S23 (Short piece 120mm)

GN series (Standard model 6~40 m/min)

GN Shortpiece 120mm

Feed speed: 6~40 m/min

Planing width: 10~230mm

Planing thickness: 7~160mm

Feed speed: 6~40 m/min

Planing width: 10~230mm

Planing thickness: 7~160mm

GAU JING GN Shortpiece series 4 side planer & moulder offer unbeatable accuracy and productivity designed for planing short pieces. The cast iron construction is designed and engineered to meet industry requirements for medium production and fine surface effect. It promises dramatic performance gains with many fine features: Rugged constructed throughout for maximum stability; High precision spindle creates extremely fine surface effect; Centralized air pressure regulations and centralized lubrication system for added convenience. The machine feeding speed is up to 60m/min saving a lot of working time. Special with automatic chain type feed machine (with 3M conveyer) which is fluent and fast feeding for the short pieces.

FEATURES

OPTIONAL:

OPTIONAL:

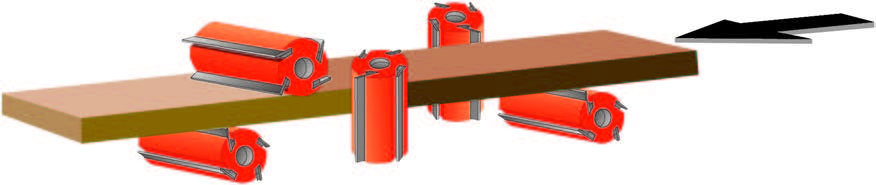

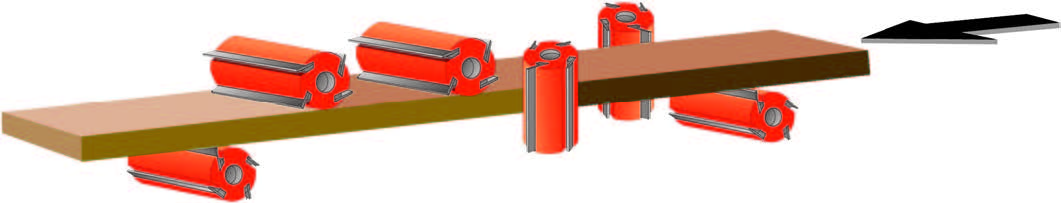

SPINDLE CONFIGURATION

SPECIFICATIONS

SPECIFICATIONS

| MODEL | GN-5S23 | GN-6S23 |

| CAPACITY | ||

| Planing width | 10-230MM | 10-230MM |

| Planing thickness | 7-160MM | 7-160MM |

| Min. working length | 120MM | 120MM |

| Feeding speed with Inverter control | 6-60M/MIN | 6-60M/MIN |

| SPINDLE | ||

| Spindle speed | 6000RPM | 6000RPM |

| Spindle diameter | Φ40MM | Φ40MM |

| Vertical spindle adjustment | 60MM | 60MM |

| Horizontal spindle adjustment | 20MM | 20MM |

| CUTTER DIAMETER | ||

| 1st bottom spindle | Φ125-160MM | Φ125-160MM |

| Vertical spindle | Φ100-180MM | Φ100-180MM |

| Top horizontal spindle | Φ100-200MM | Φ100-200MM |

| Last bottom spindle | Φ100-250MM | Φ100-250MM |

| MOTOR | ||

| 1st bottom spindlle | 7.5HP | 7.5HP |

| Vertical spindle | 10HP | 10HP |

| Top spindle | 10HP | 10HP |

| Last bottom spindle | 10HP | 10HP |

| Feeding motor (inverter) | 5HP | 7.5HP |

| Elevation motor | 1/2HP | 1/2HP |

| OTHERS | ||

| Table adjustment | 12MM | 12MM |

| Infeed table length | 1300MM | 1300MM |

| Machine diamension (LxWxH) | 6130x1800x1840MM | 6675x1800x1840MM |

| Packing dimension (LxWxH) | 3200x2080x2120MM+ 2340x560x1120MM |

3800x2080x2120MM+ 2340x560x1120MM |

| Net weight | 3900KGS | 4400KGS |

| *SPECIFICATIONS AND DESIGN CHARACTERISTICS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE. | ||