Feed speed: 6~40 m/min

Planing width: 10~230mm

Planing thickness: 7~160mm

The compact design never sacrifices quality

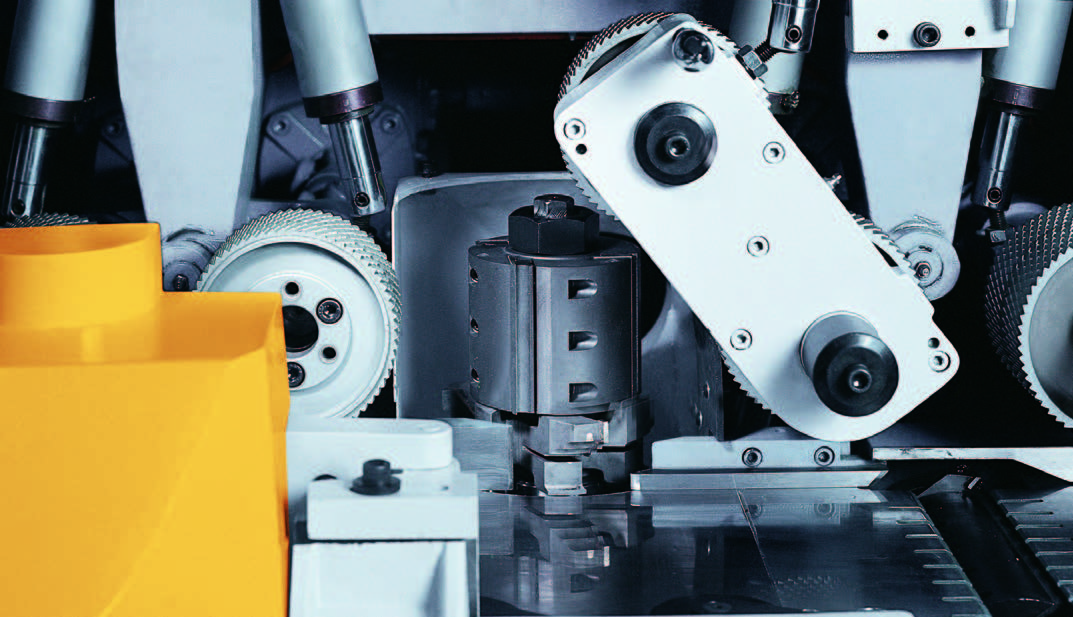

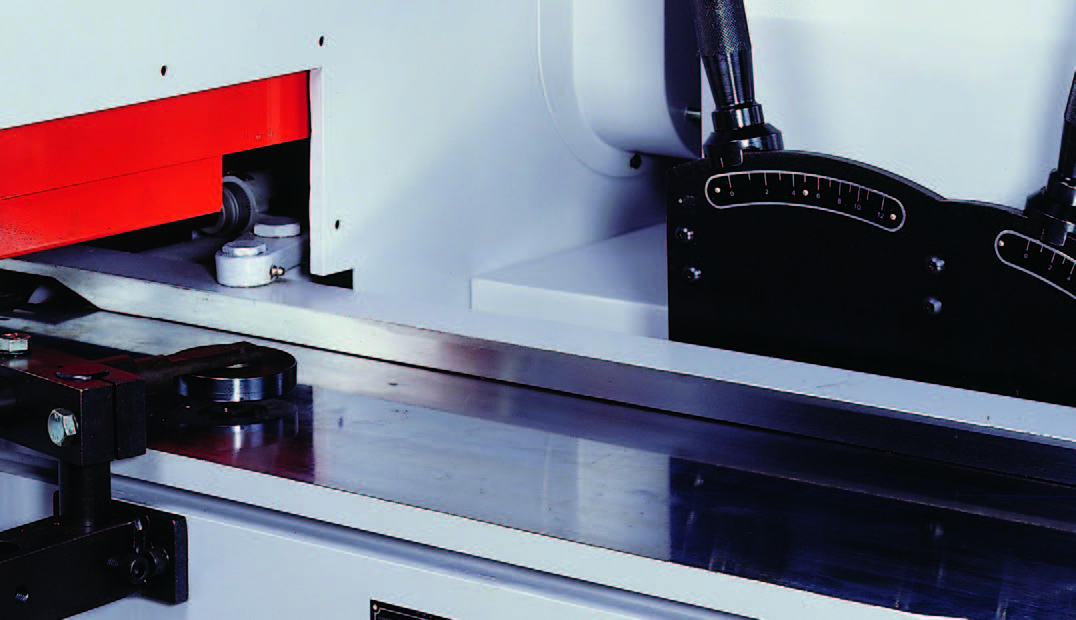

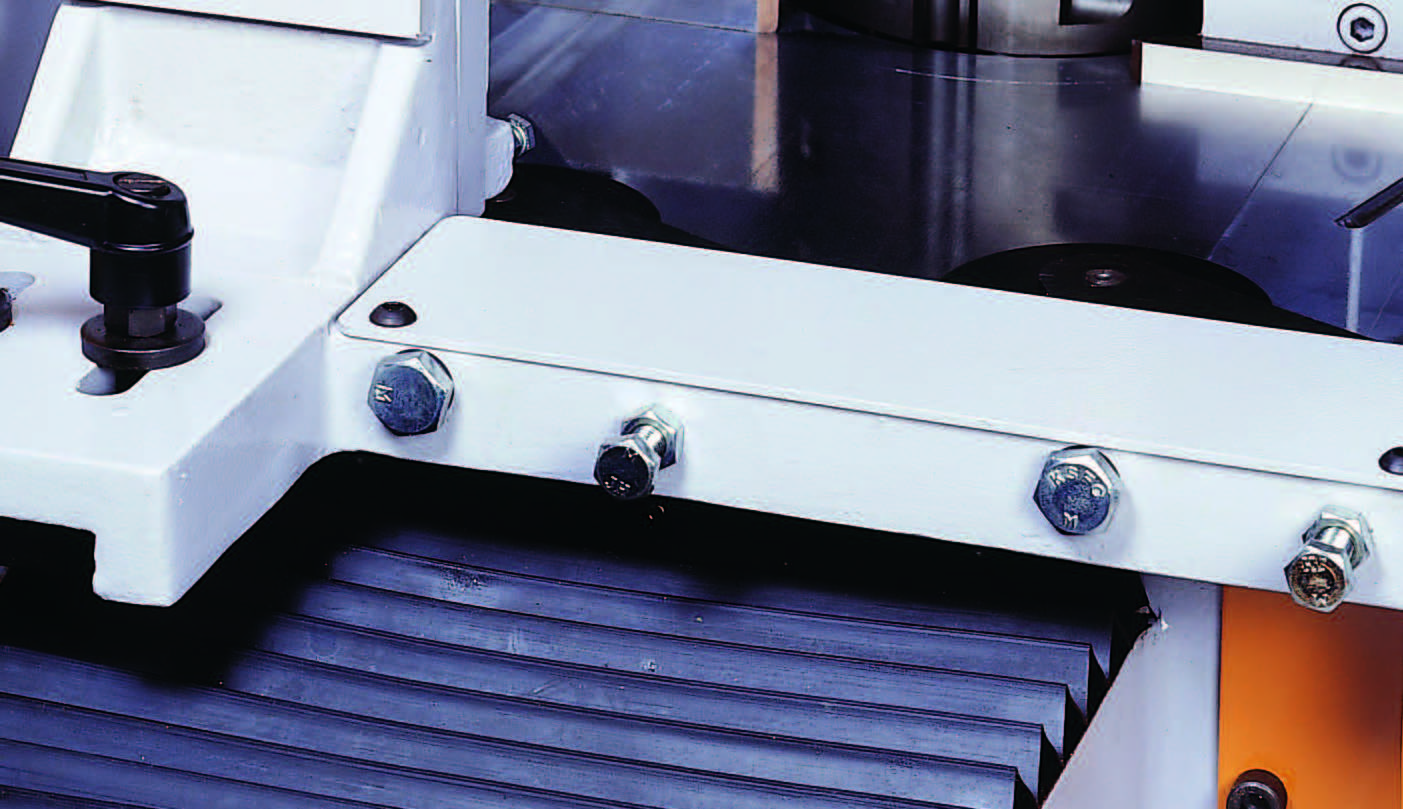

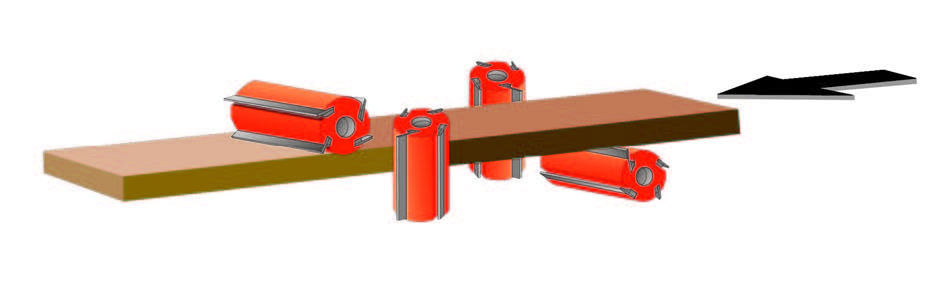

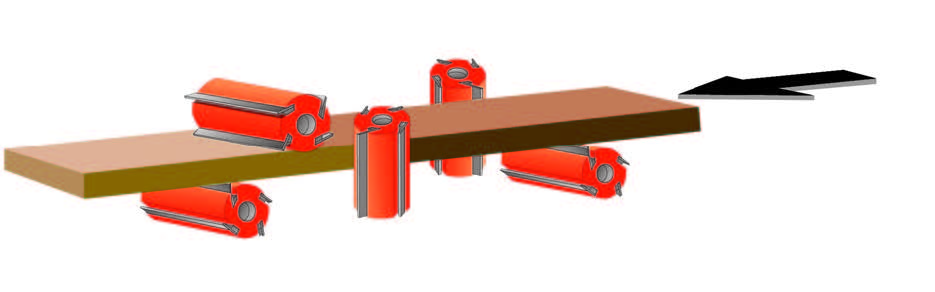

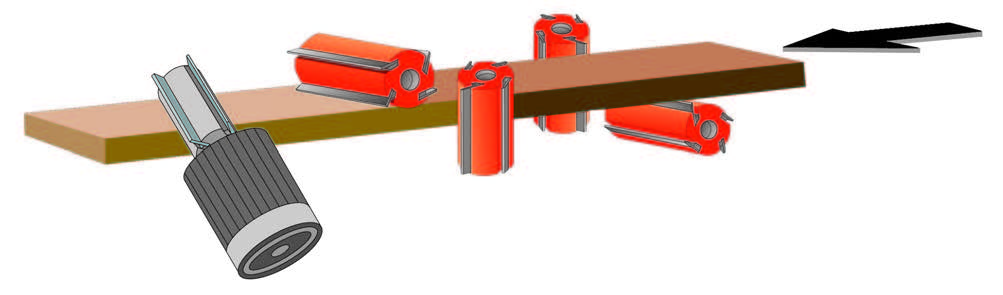

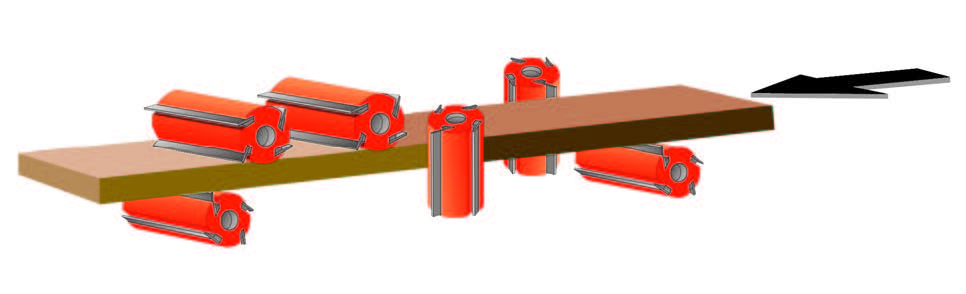

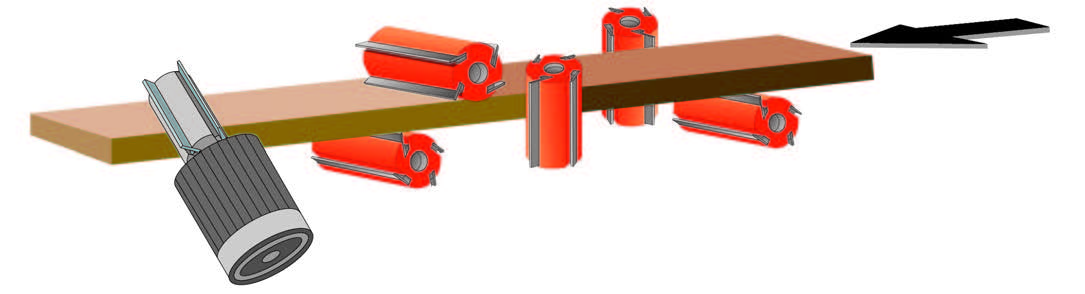

For over a long time, operators have searched for a 4-side moulder that is economically priced, but without sacrificing machine efficiency and quality. GAU JING New GS series 4-side moulder is just the machine that meets all these objectives as you have expected. The massive machine frame is manufactured from cast iron, and rib reinforced to provide maximum rigidity and stability.

All control levers for the spindles are located at front of the machine for convenient adjustment. Variable feed speed makes this machine ideal for cutting all types of wood material. Side front pressure plate on the left vertical spindle assures smooth feeding for short or narrow workpieces. The entire machine is designed to integrate many fine features normally expected only from a big machine. Each machine produced is backed with GAU JING’s tradition of quality that you can trust.

OPTIONAL:

SPECIFICATIONS

| MODEL | GS-423 | GS-523 | GS-623 | GS-523U | GS-623U |

| CAPACITY | |||||

| Planing width | 10-230MM | 10-230MM | 10-230MM | 10-230MM | 10-230MM |

| Planing thickness | 7-125MM | 7-125MM | 7-125MM | 7-125MM | 7-125MM |

| Min. working length | 230MM | 230MM | 230MM | 230MM | 230MM |

| Feed speed | 6-25M/MIN | 6-25M/MIN | 6-25M/MIN | 6-25M/MIN | 6-25M/MIN |

| SPINDLE | |||||

| Spindle speed | 6000RPM | 6000RPM | 6000RPM | 6000RPM | 6000RPM |

| Spindle diameter | Φ40MM | Φ40MM | Φ40MM | Φ40MM | Φ40MM |

| Vertical spindle adjustment (axial) | 30MM | 30MM | 30MM | 30MM | 30MM |

| Horizontal spindle adjustment (axial) | 20MM | 20MM | 20MM | 20MM | 20MM |

| CUTTER DIAMETER | |||||

| 1st bottom spindle | Φ100-150MM | Φ100-150MM | Φ100-150MM | Φ100-150MM | Φ100-150MM |

| Vertical spindle | Φ100-180MM | Φ100-180MM | Φ100-180MM | Φ100-180MM | Φ100-180MM |

| Top spindle | Φ100-180MM | Φ100-180MM | Φ100-180MM | Φ100-180MM | Φ100-180MM |

| Last bottom spindle | - | Φ100-205MM | Φ100-205MM | - | Φ100-205MM |

| Universal spindle | - | - | - | Φ100-180MM | Φ100-180MM |

| MOTOR | |||||

| 1st bottom spindle | 7.5HP | 7.5HP | 7.5HP | 7.5HP | 7.5HP |

| Vertical spindle (1 motor) | 10HP | 10HP | 15HP | 10HP | 10HP |

| Top spindle | 7.5HP | 7.5HP | 7.5HP | 7.5HP | 7.5HP |

| Last bottom spindle | - | 7.5HP | 7.5HP | - | 7.5HP |

| Universal spindle | - | - | - | 5HP | 5HP |

| Feeding motor | 3HP | 3HP | 5HP | 3HP | 3HP |

| Elevation motor | 1/3HP | 1/3HP | 1/3HP | 1/3HP | 1/3HP |

| OTHERS | |||||

| Table adjustment | 12MM | 12MM | 12MM | 12MM | 12MM |

| Infeed table length | 2000MM | 2000MM | 2000MM | 2000MM | 2000MM |

| Machine dimensions (LxWxH) | 3230x1300x1710MM | 3345x1300x1710MM | 3895x1300x1710MM | 4045x1300x1710MM | 4170x1300x1710MM |

| Packing dimensions (LxWxH) | 2280x1450x1960MM | 2320x1450x1960MM | 3030x1450x1960MM | 3030x1800x1960MM | 3150x1800x1960MM |

| Net weight | 2500KGS | 2800KGS | 3000KGS | 3600KGS | 4200KGS |

| *SPECIFICATIONS AND DESIGN CHARACTERISTICS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE. | |||||