Feed speed: 6~40/60/80/100/120/150 m/min

Planing width: 10-230mm

Planing thickness: 7-160mm

Superior Value in Performance Moulder

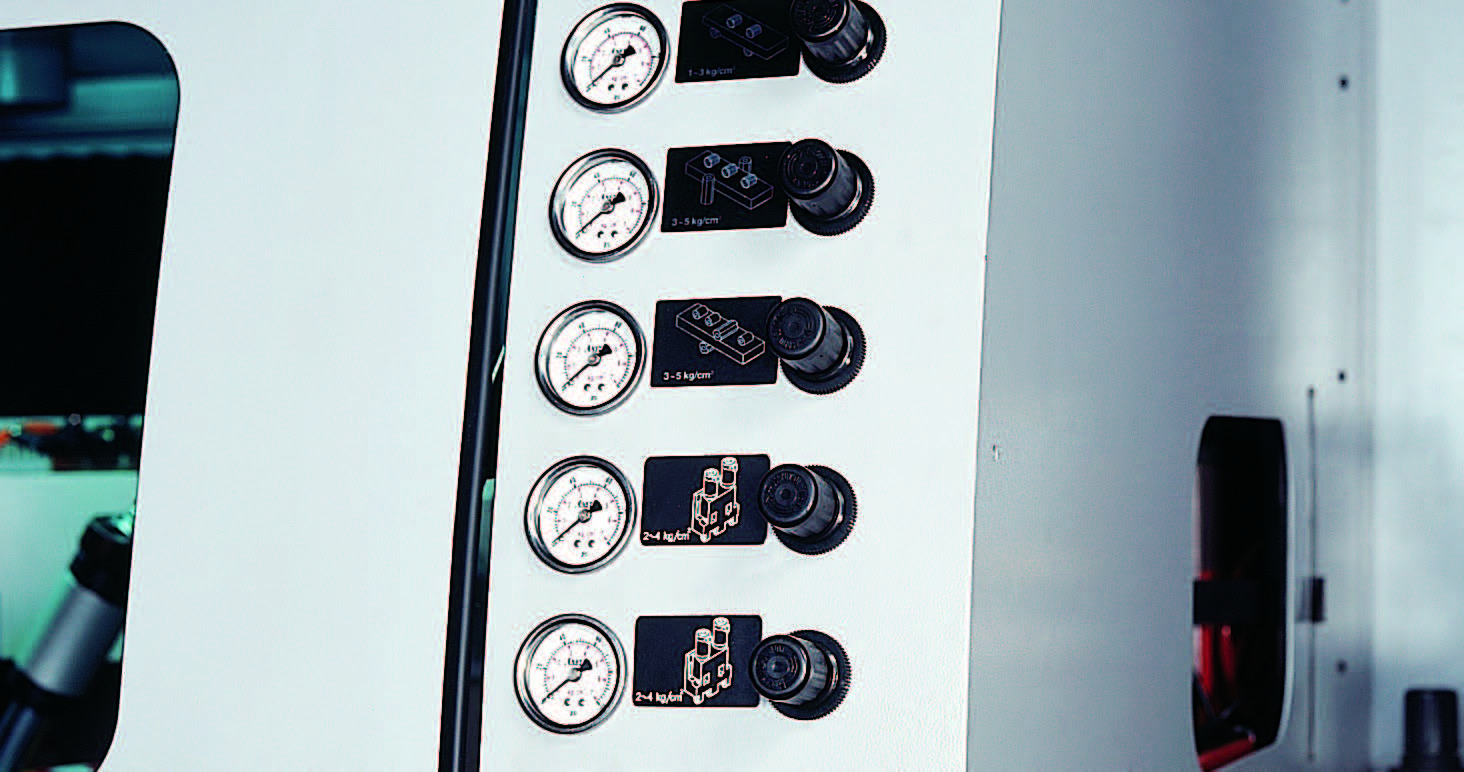

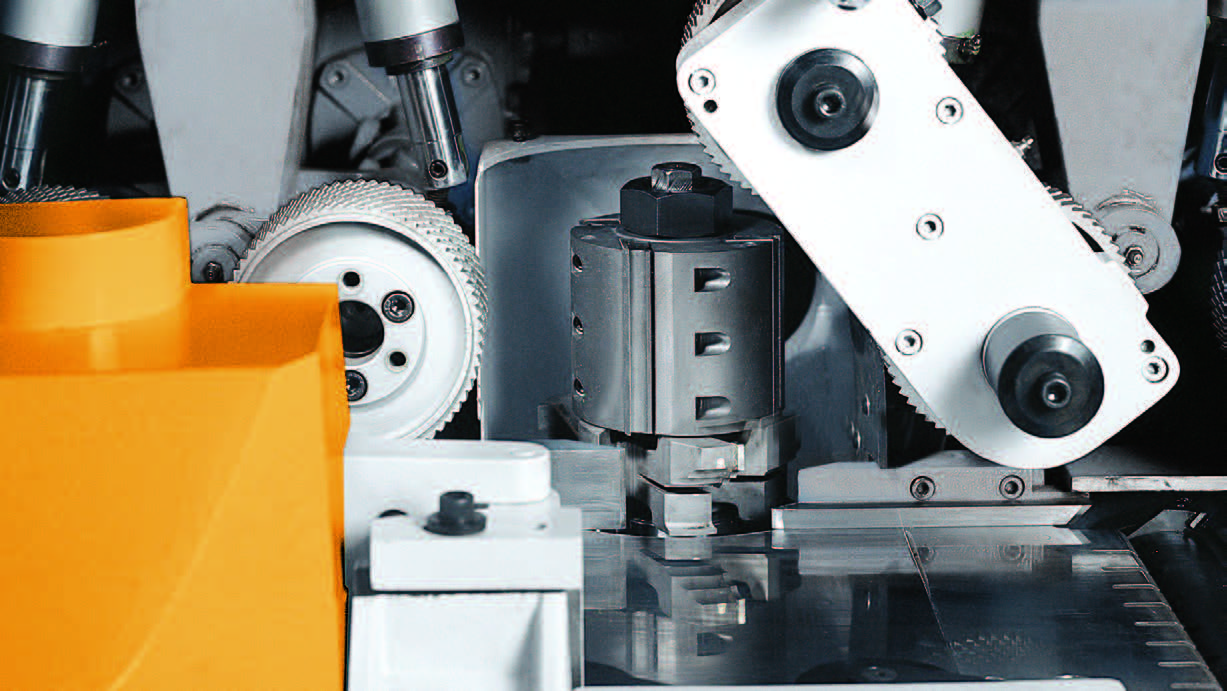

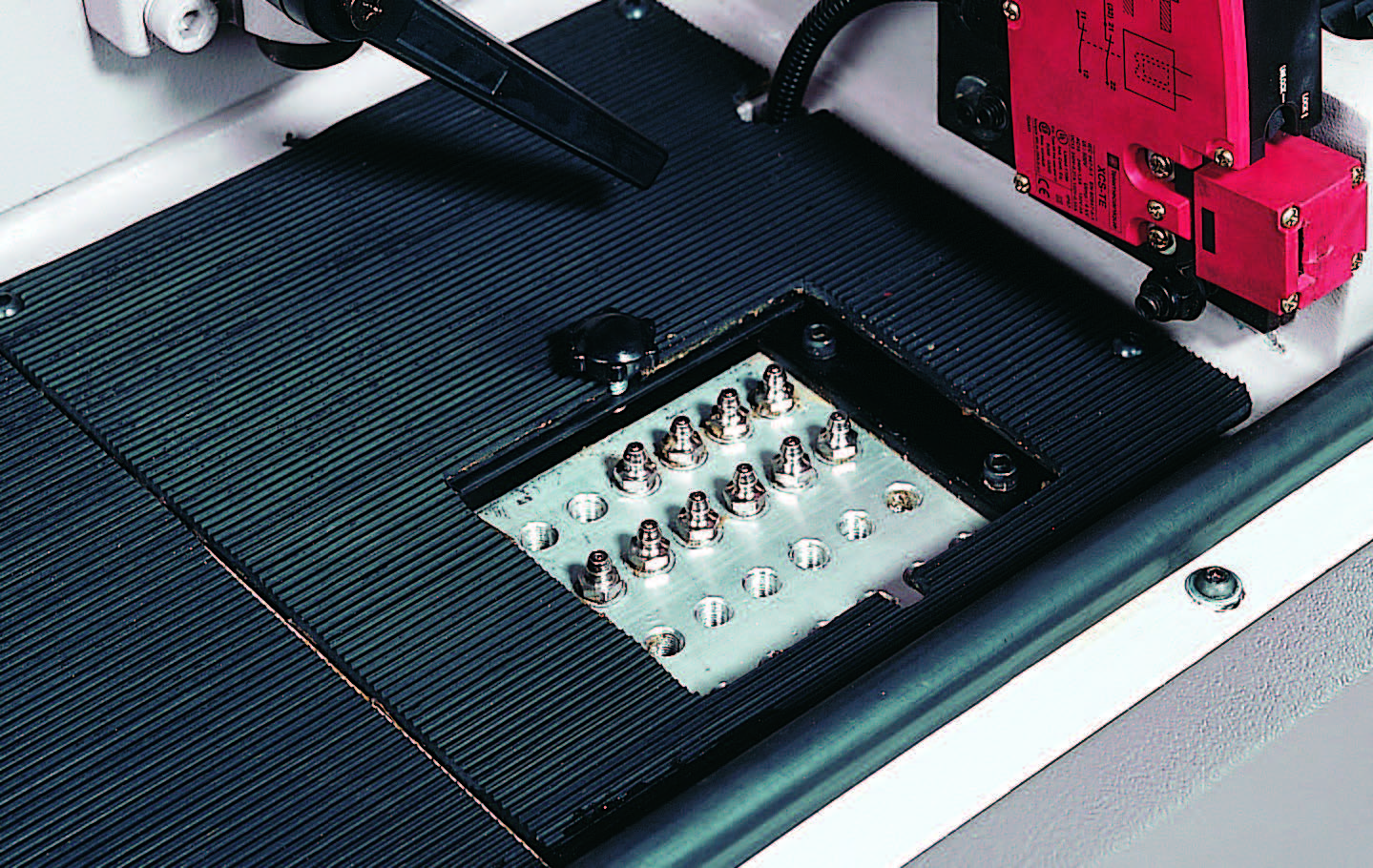

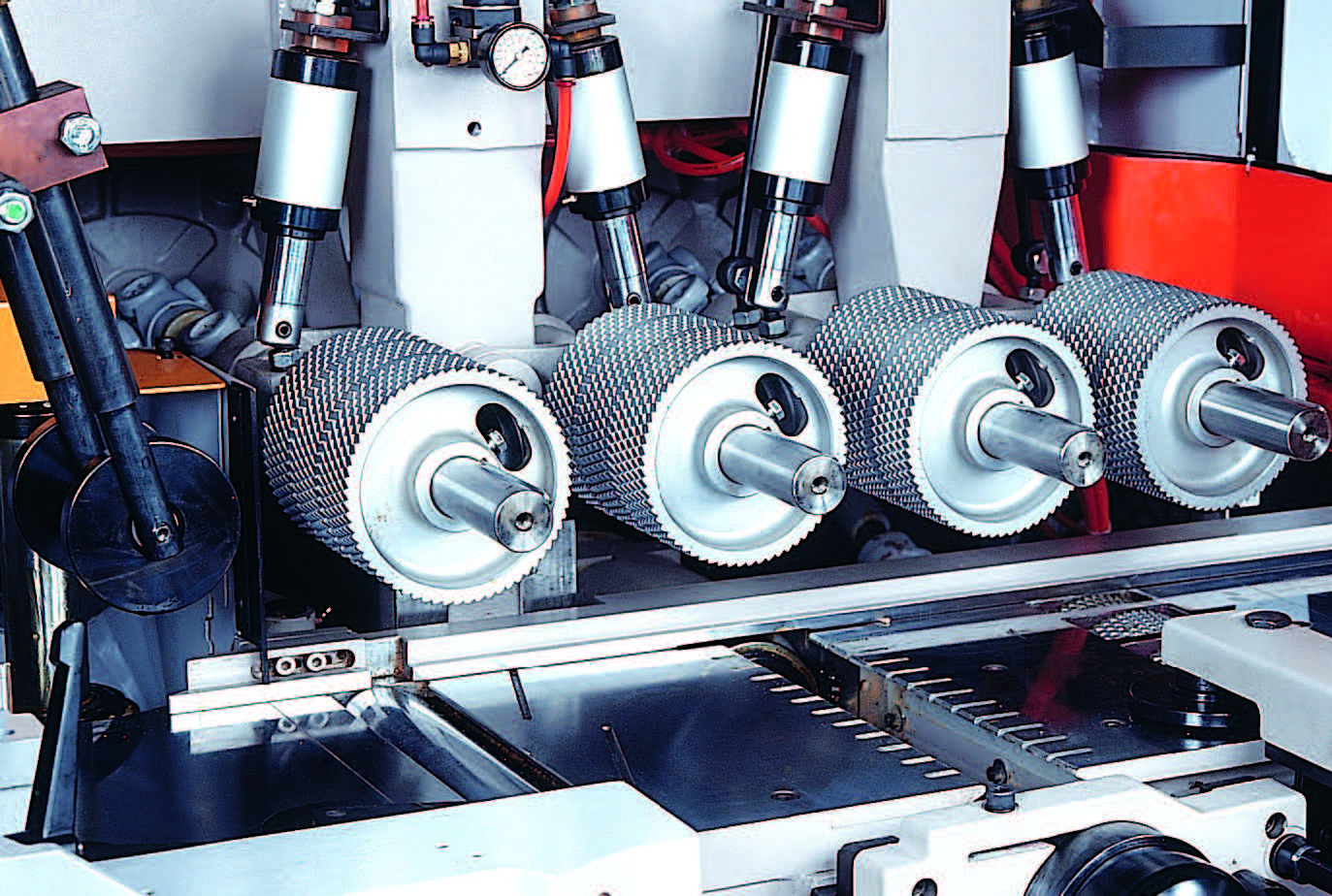

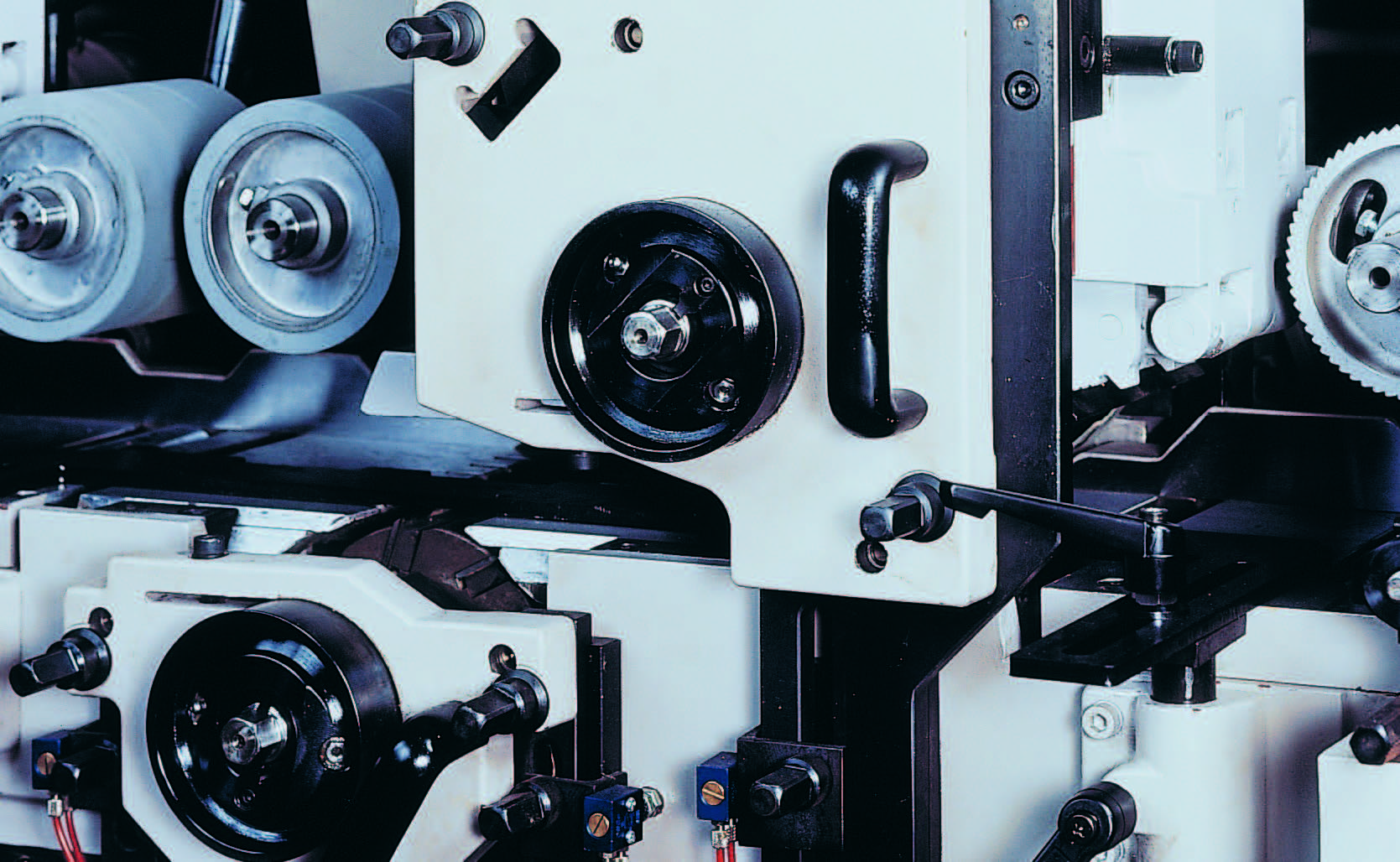

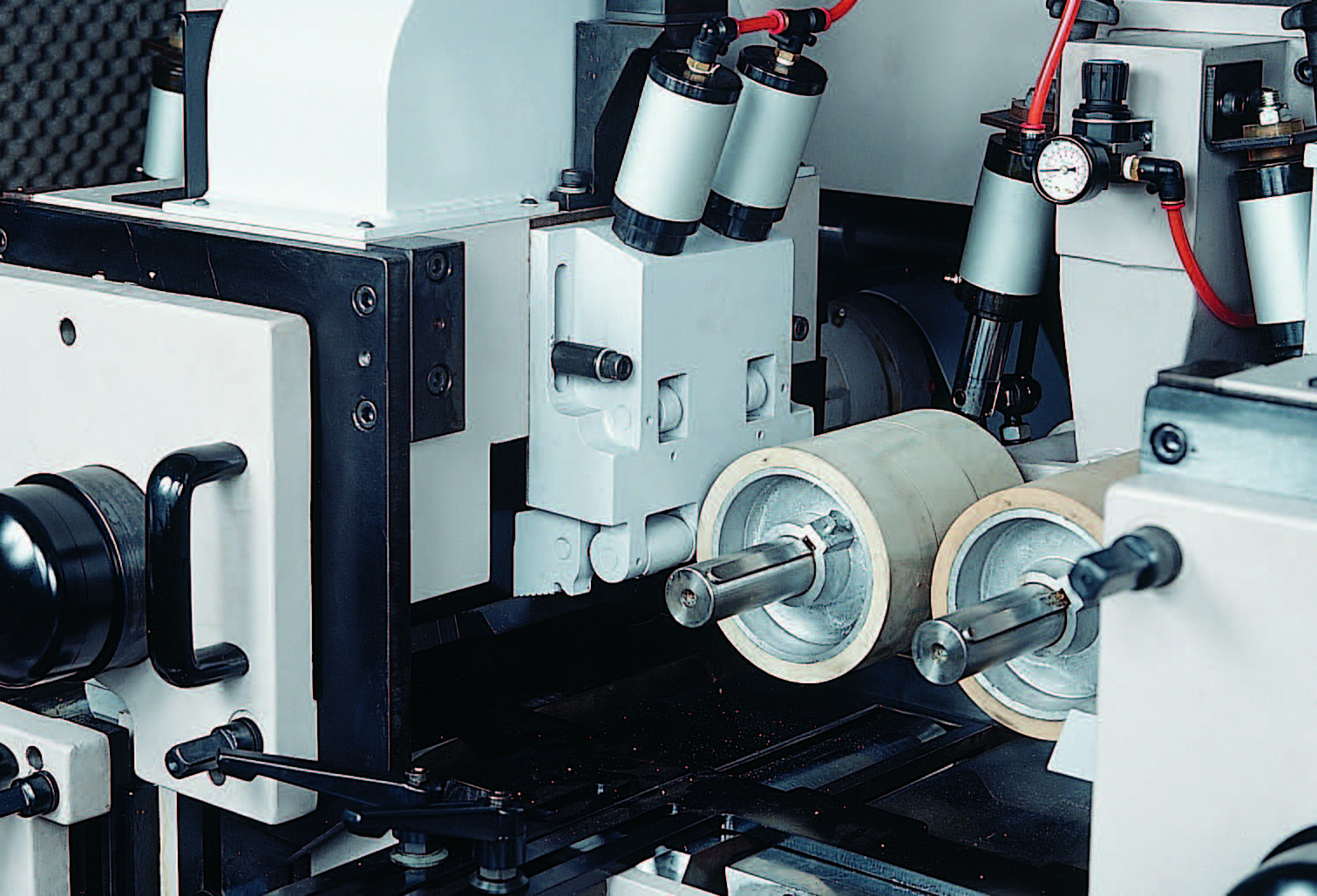

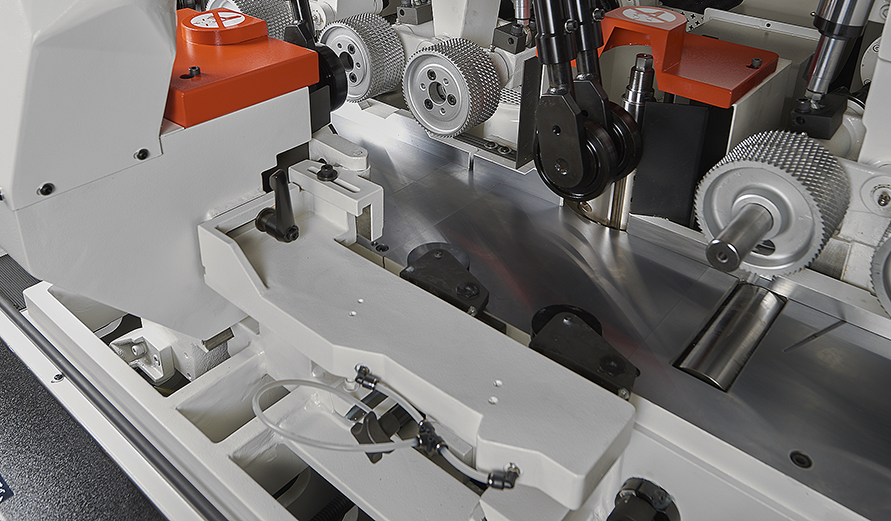

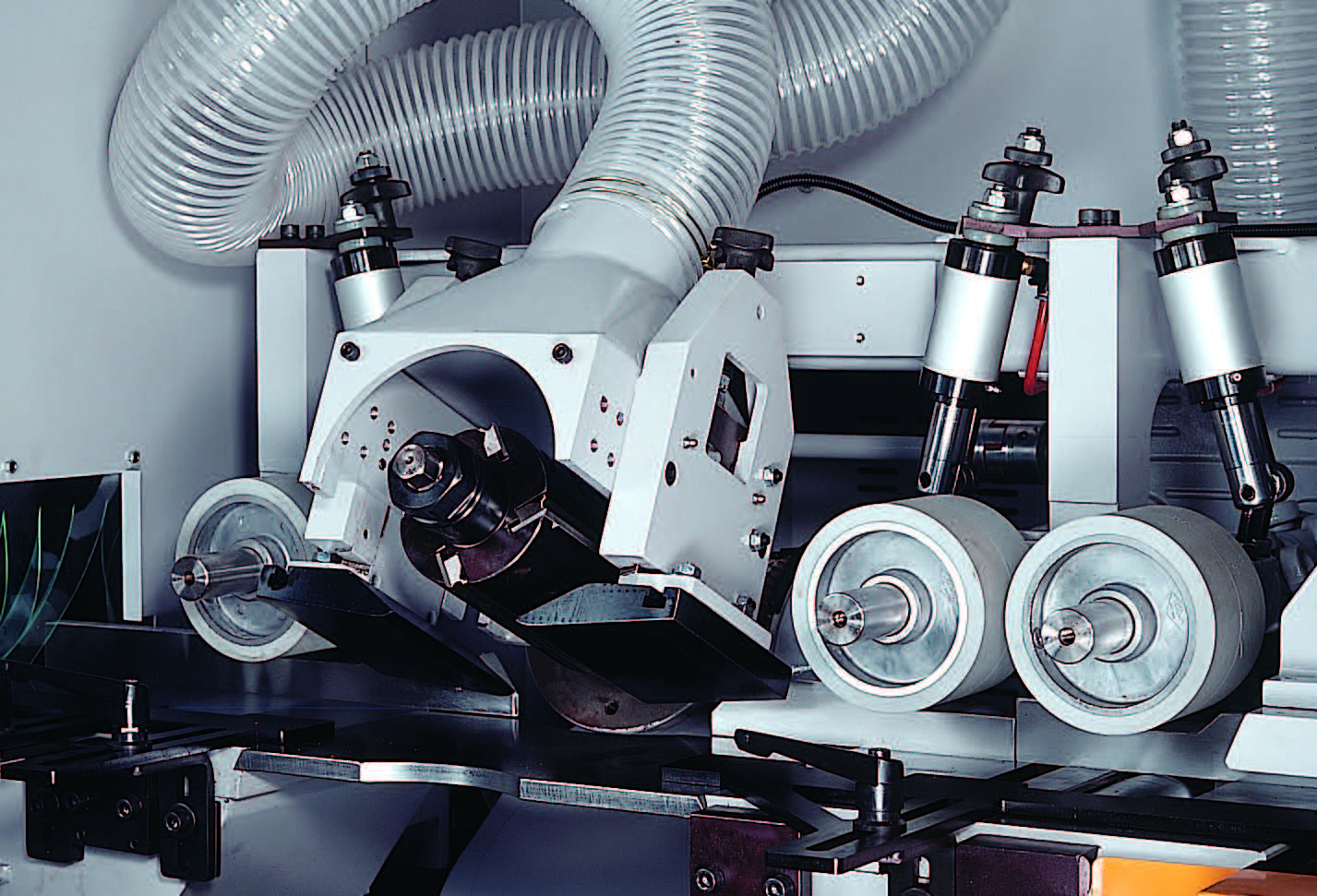

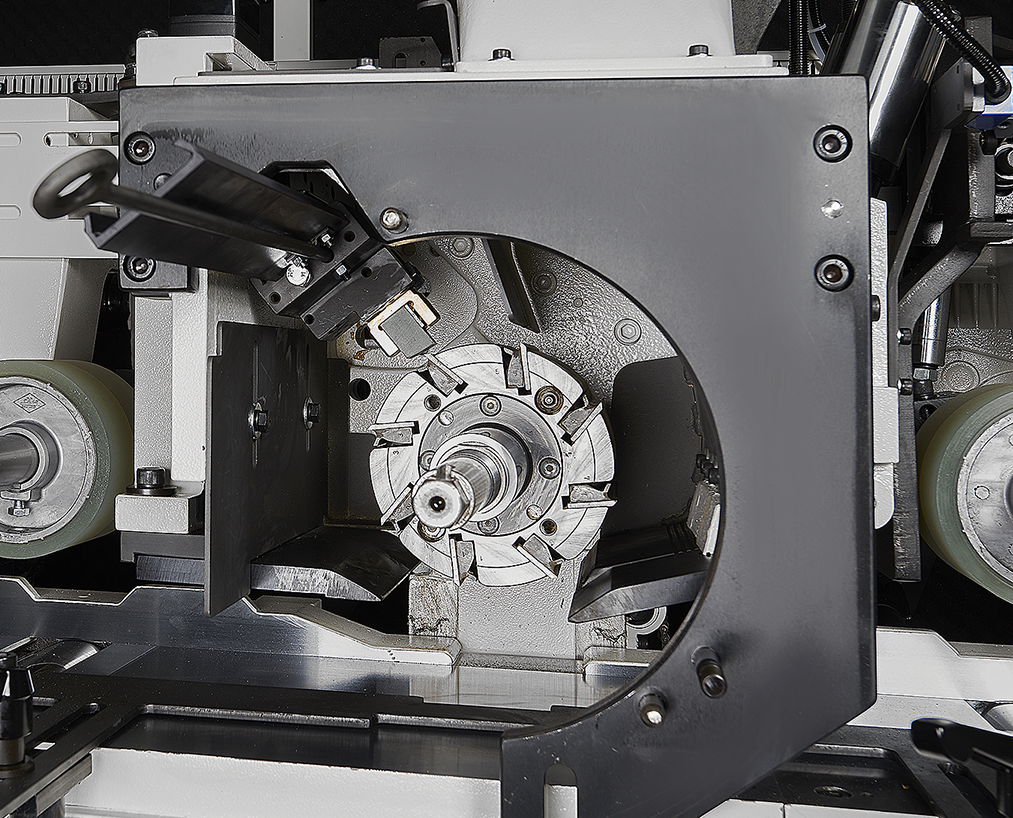

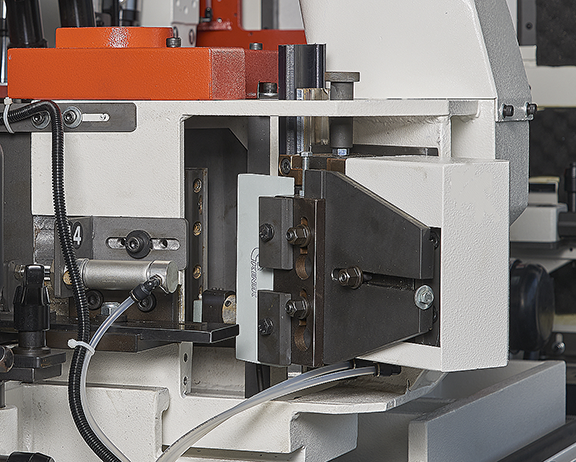

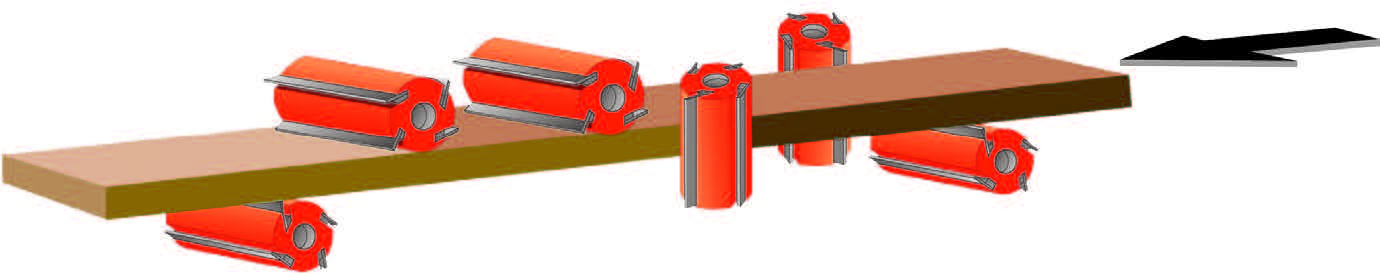

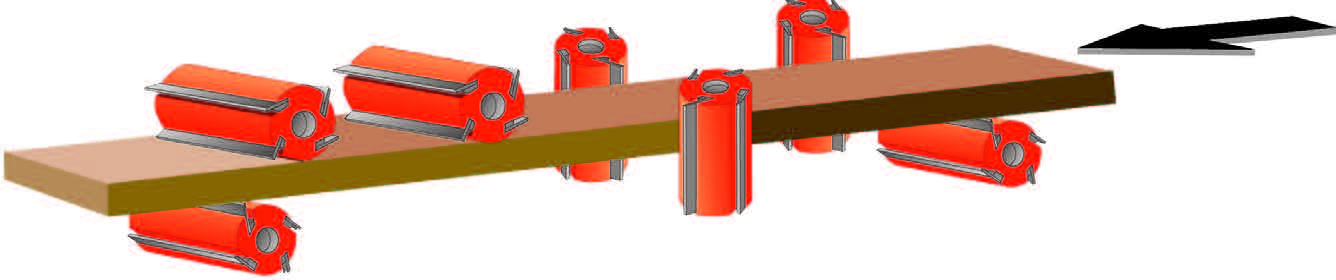

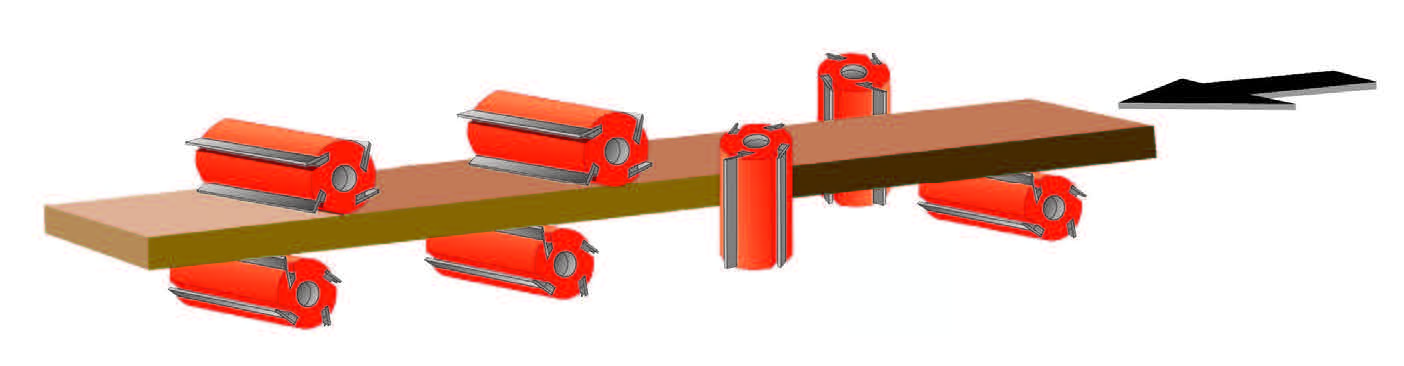

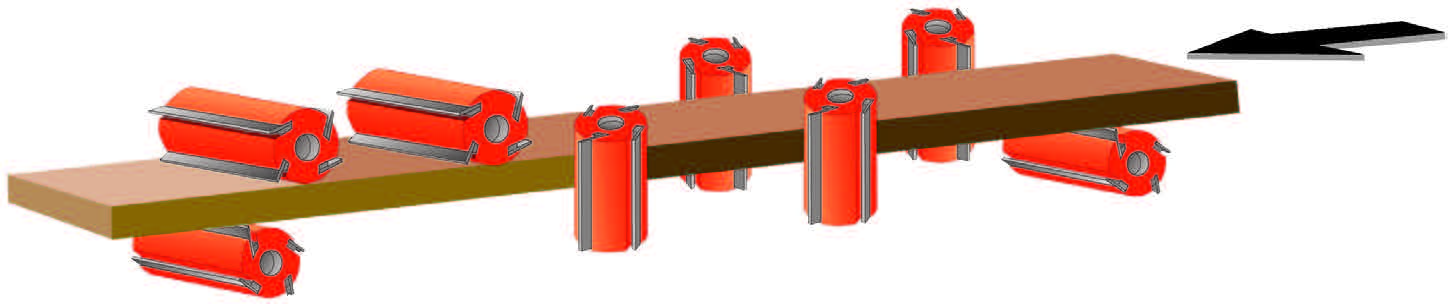

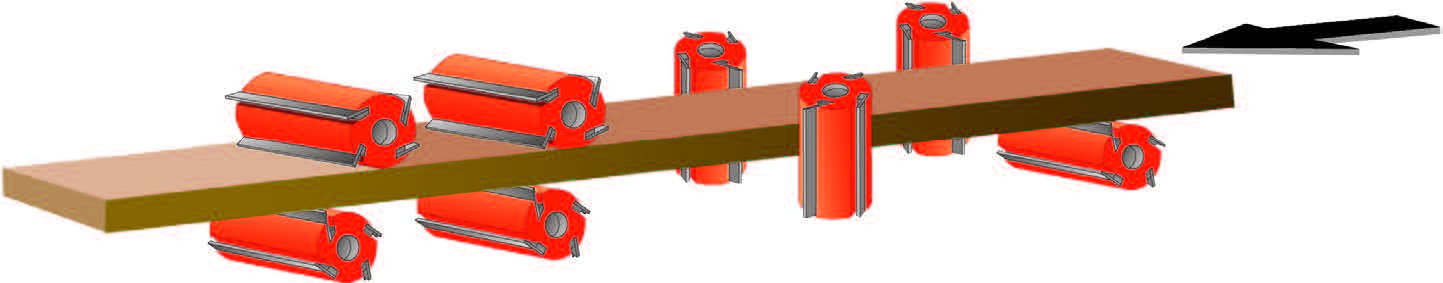

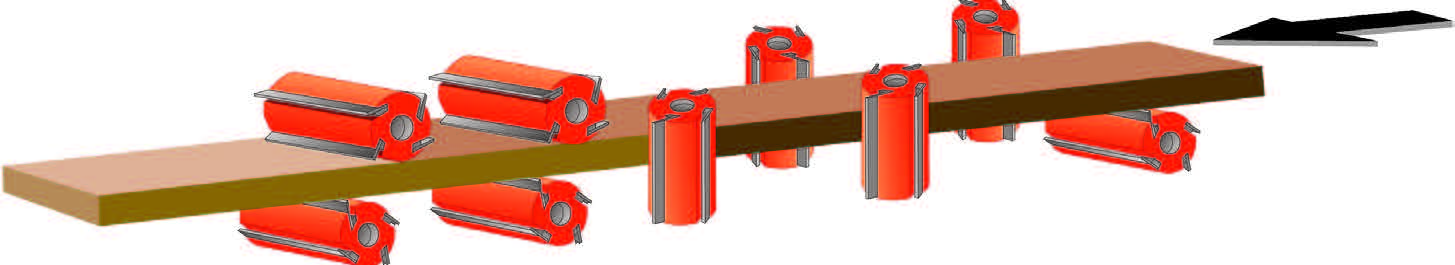

GA series is an ideal moulder for small and mass production. With its optional 60 or 80 m/min feed speed could get a high productivity. This moulder is designed and engineered to meet those who require heavy duty machine. The spindle is precision manufactured and dynamically balanced combined with hydraulic outboard bearing support, assuring maximum stability during cutting.

The entire machine frame is ruggedly constructed throughout by high quality cast iron, so the moulder features optimum rigidity and stability for years of operations. Comprehensive optional equipments are available to upgrade operational convenience and performance level, such as profile jointer, straight jointer, ATS system and more. Precision, Productivity, Quality, Dependability. All things you’ve come to expect could be found on the GAU JING GA series 4-side Planer & Moulder.

OUTSTANDING FEATURES

OPTIONAL:

SPECIFICATIONS

| MODEL | GA-623 | GA-723 | GA-723A | GA-823 | GA-923 |

| CAPACITY | |||||

| Planing width | 10-230MM | 10-230MM | 10-230MM | 10-230MM | 10-230MM |

| Planing thickness | 7-160MM | 7-160MM | 7-160MM | 7-160MM | 7-160MM |

| Feeding speed (Inverter) | 6-40M/MIN | 6-40M/MIN | 6-40M/MIN | 6-40M/MIN | 6-40M/MIN |

| Min. working length | 230MM | 230MM | 230MM | 230MM | 230MM |

| SPINDLE | |||||

| Spindle speed | 6000RPM | 6000RPM | 6000RPM | 6000RPM | 6000RPM |

| Spindle diameter | Φ40/Φ50MM | Φ40/Φ50MM | Φ40/Φ50MM | Φ40/Φ50MM | Φ40/Φ50MM |

| Vertical spindle adjustment (axial) | 60MM | 60MM | 60MM | 60MM | 60MM |

| Horizontal spindle adjustment (axial) | 35MM | 35MM | 35MM | 35MM | 35MM |

| CUTTER DIAMETER | |||||

| 1st bottom spindle | Φ110-180MM | Φ110-180MM | Φ110-180MM | Φ110-180MM | Φ110-180MM |

| Vertical spindle | Φ110-250MM | Φ110-250MM | Φ110-250MM | Φ110-250MM | Φ110-250MM |

| Top spindle | Φ110-250MM | Φ110-250MM | Φ110-250MM | Φ110-250MM | Φ110-250MM |

| Last bottom spindle | Φ110-305MM | Φ110-305MM | Φ110-305MM | Φ110-305MM | Φ110-305MM |

| MOTOR | |||||

| 1st bottom spindle | 10HP | 10HP | 10HP | 10HP | 10HP |

| Vertical spindle | 10HP | 10HP | 10HP | 10HP | 10HP |

| 1st top spindle | 15HP | 15HP | 15HP | 15HP | 15HP |

| 2nd top spindle | 10HP | 10HP | 10HP | 10HP | 10HP |

| Last bottom spindle | 15HP | 15HP | 15HP | 15HP | 15HP |

| Feeding motor (Inverter) | 10HP | 10HP | 10HP | 15HP | 15HP |

| Elevation motor | 1HP | 1HP | 1HP | 1HP | 1HP |

| OTHERS | |||||

| Table adjustment | 12MM | 12MM | 12MM | 12MM | 12MM |

| Infeed table length | 1800MM | 1800MM | 1800MM | 1800MM | 1800MM |

| Machine dimensions (LxWxH) | 5660x2010x1890MM | 6210x2010x1890MM | 5660x2010x1890MM | 6600x2010x1890MM | 6600x2010x1890MM |

| Packing dimensions (LxWxH) | 5900x2180x2050MM | 6400x2180x2050MM | 5900x2180x2050MM | 6900x2180x2050MM | 6900x2180x2050MM |

| Net weight | 6800KGS | 7500KGS | 7200KGS | 8200KGS | 8800KGS |

| *SPECIFICATIONS AND DESIGN CHARACTERISTICS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE. | |||||