Feed speed: 6~40/60/80/100/120 m/min

Planing width: 10-300mm

Planing thickness: 7-160mm

Outstanding quality in Large dimensions

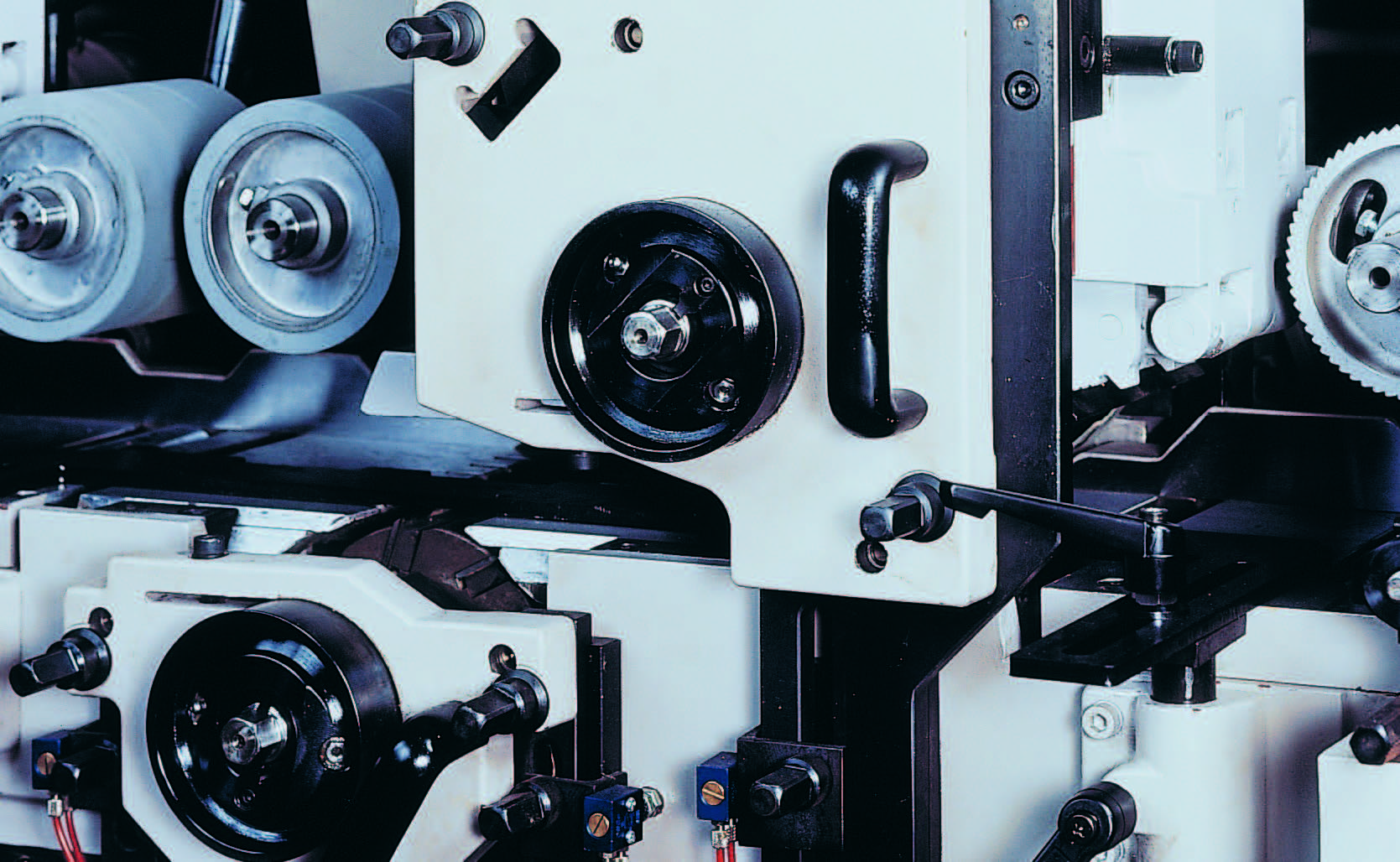

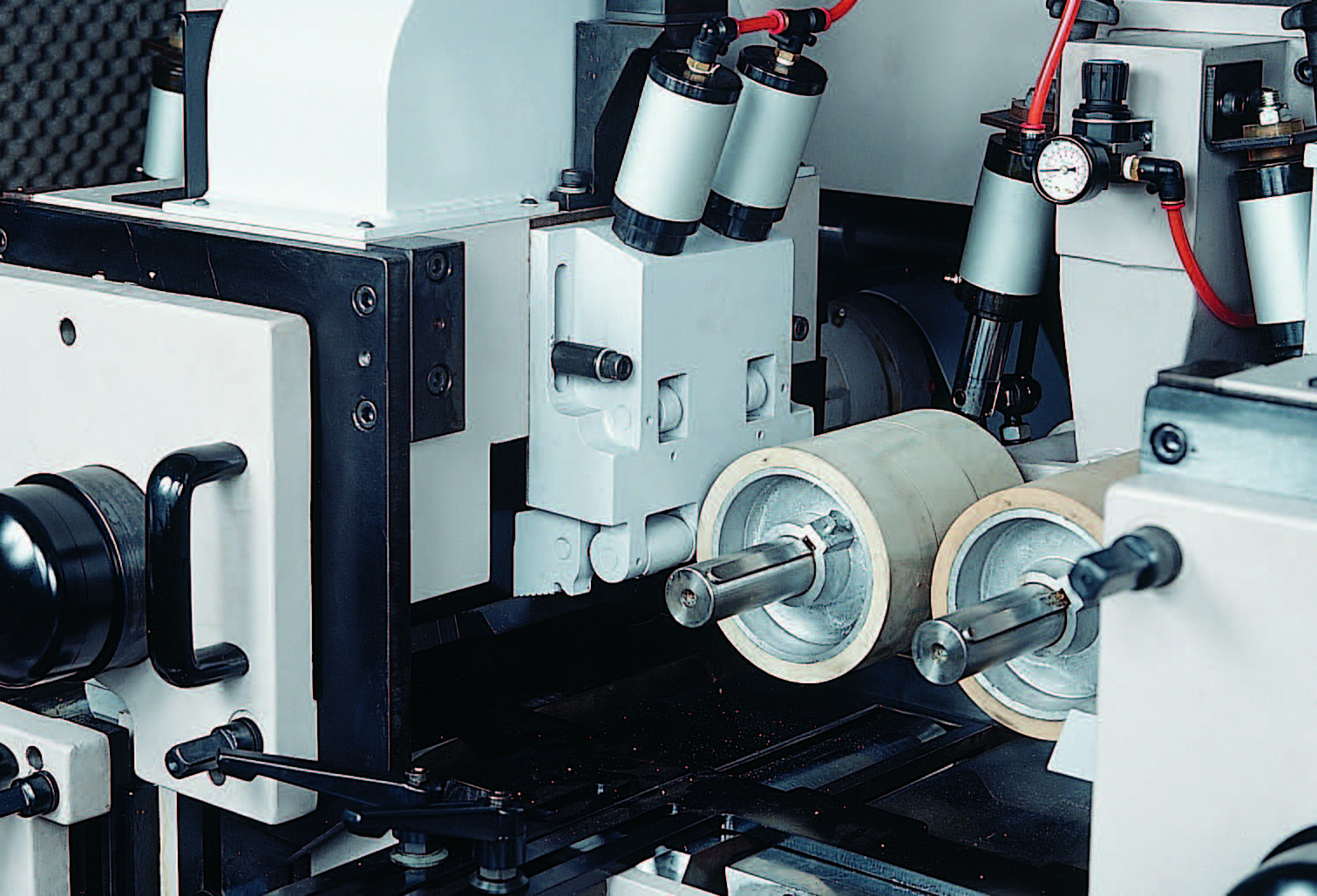

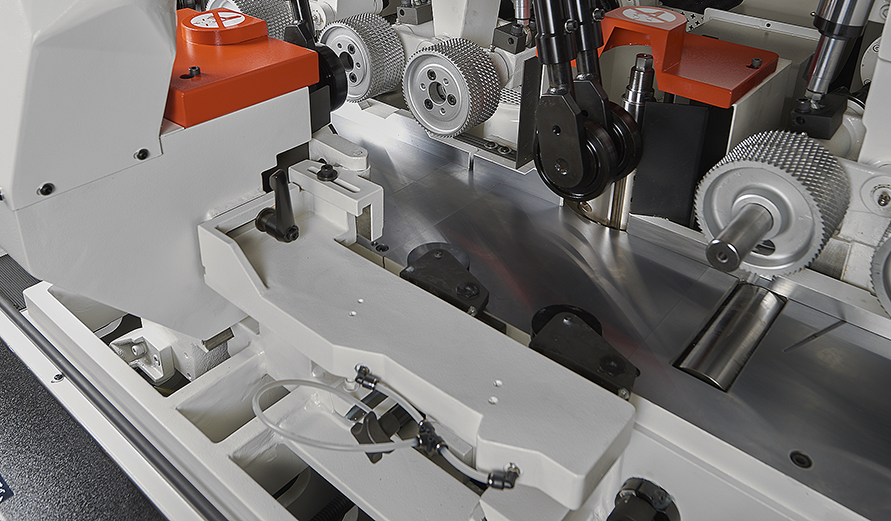

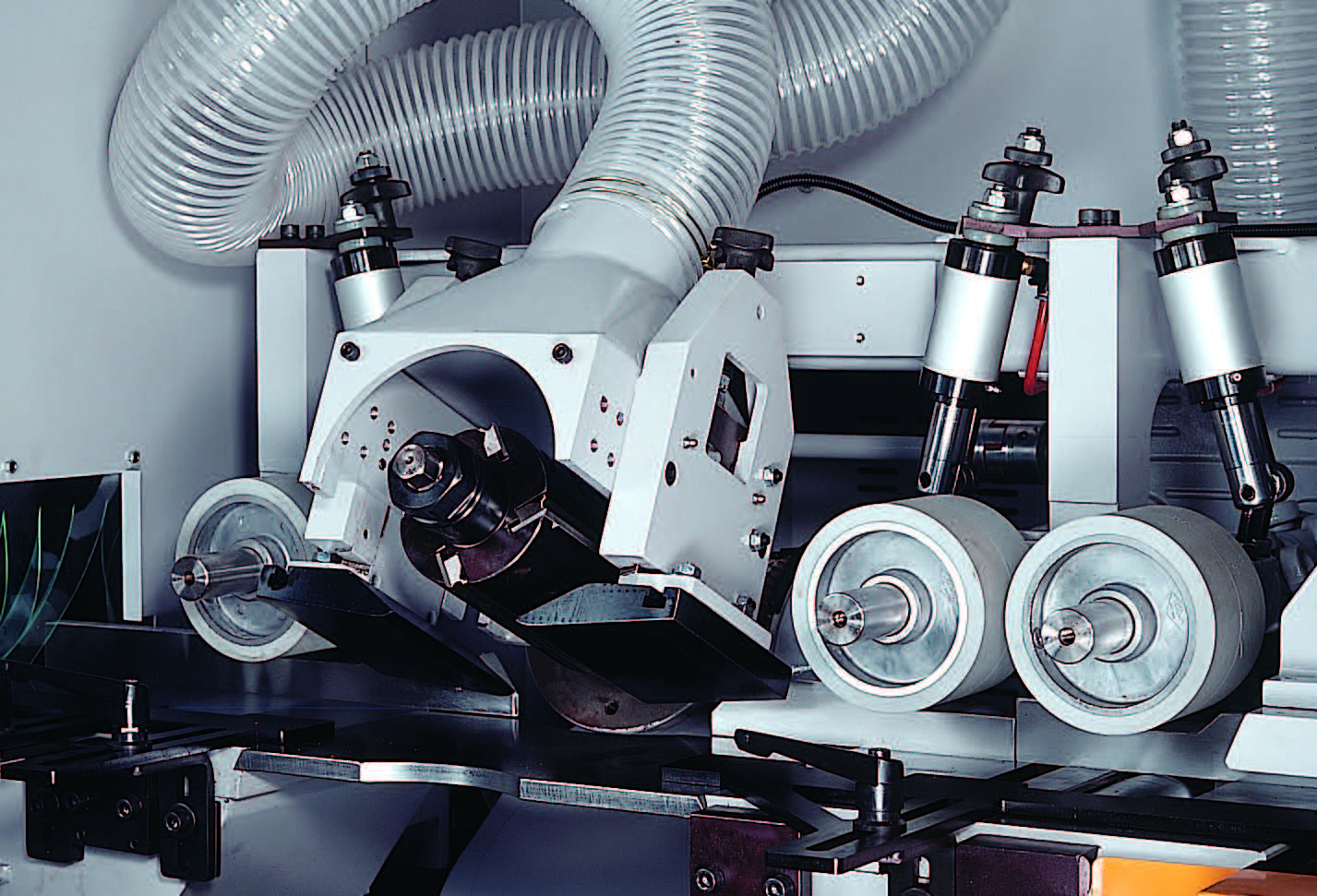

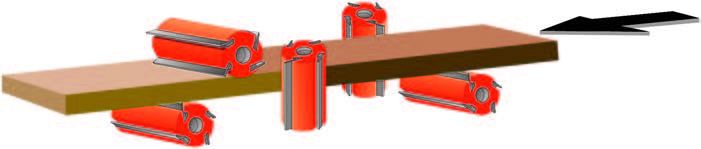

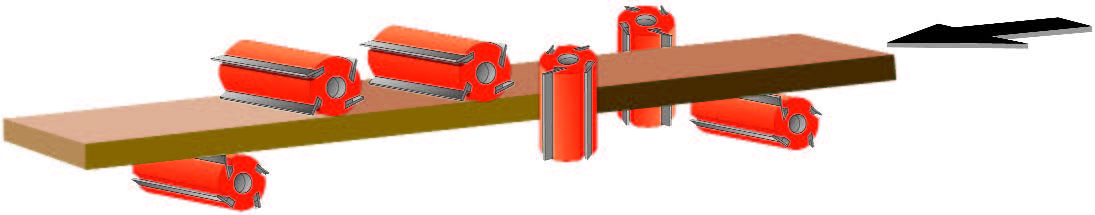

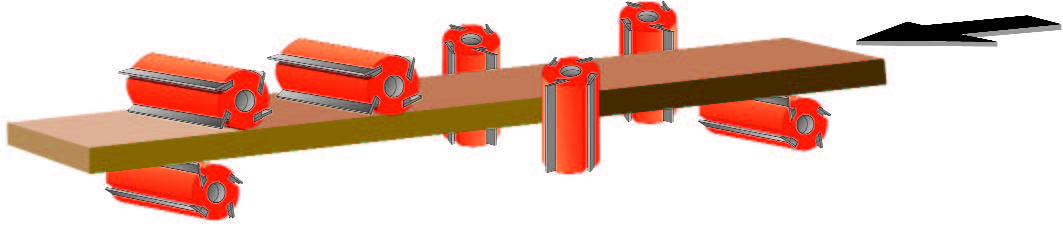

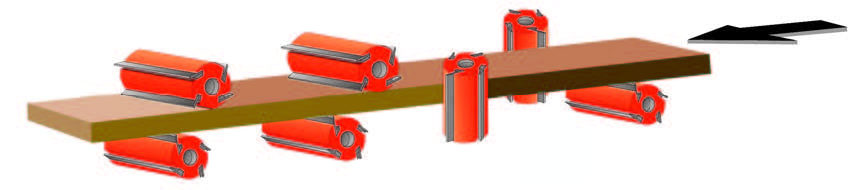

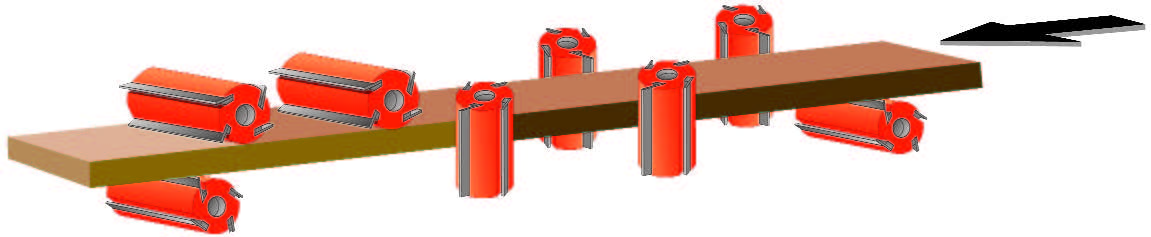

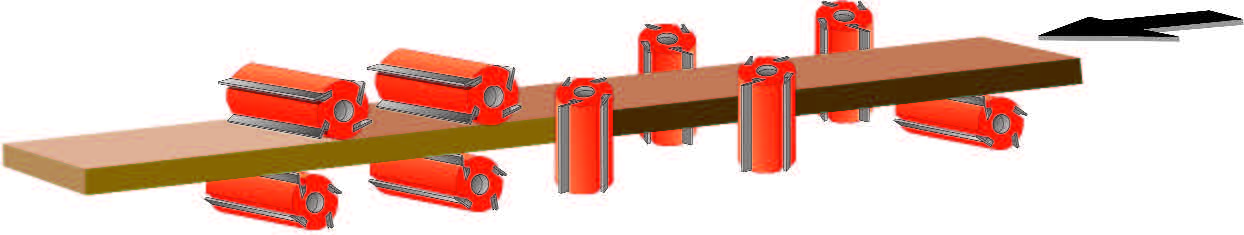

The GL series moulder is designed for heavy cutting, extra wide planing, and high productivity. For instance, this moulder makes it easy for moulding beams of a wooden house. Its rugged and precise construction throughout fully eliminates vibration and the wood pieces surface quality.

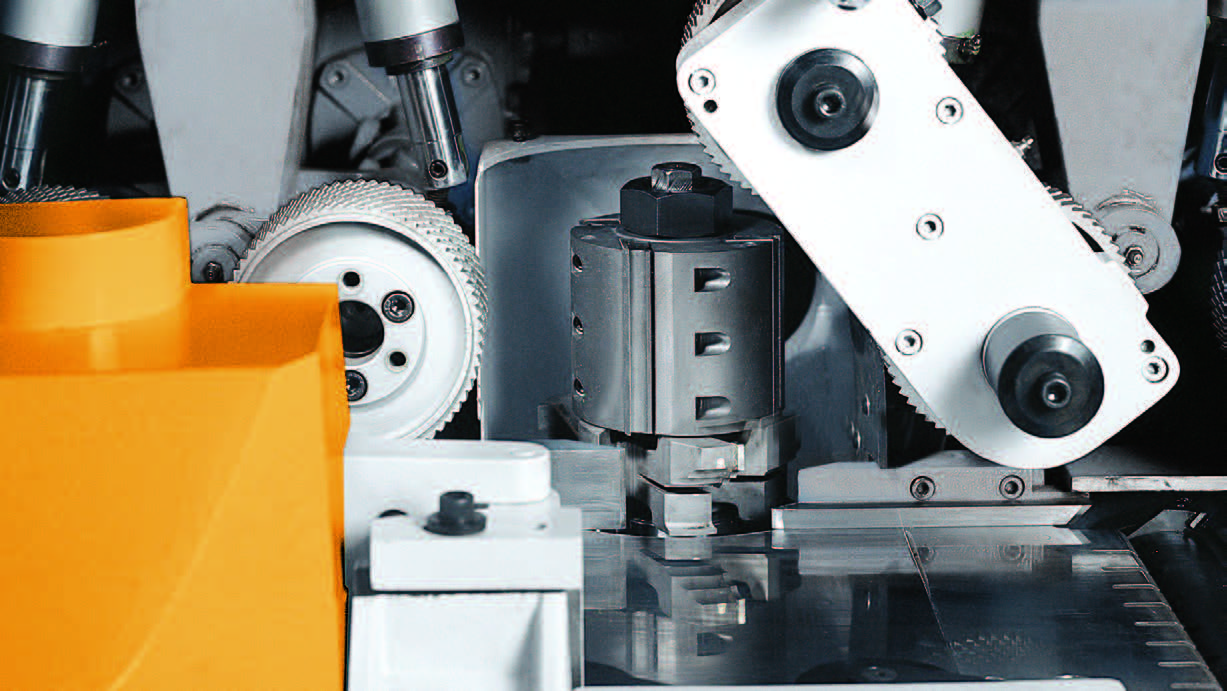

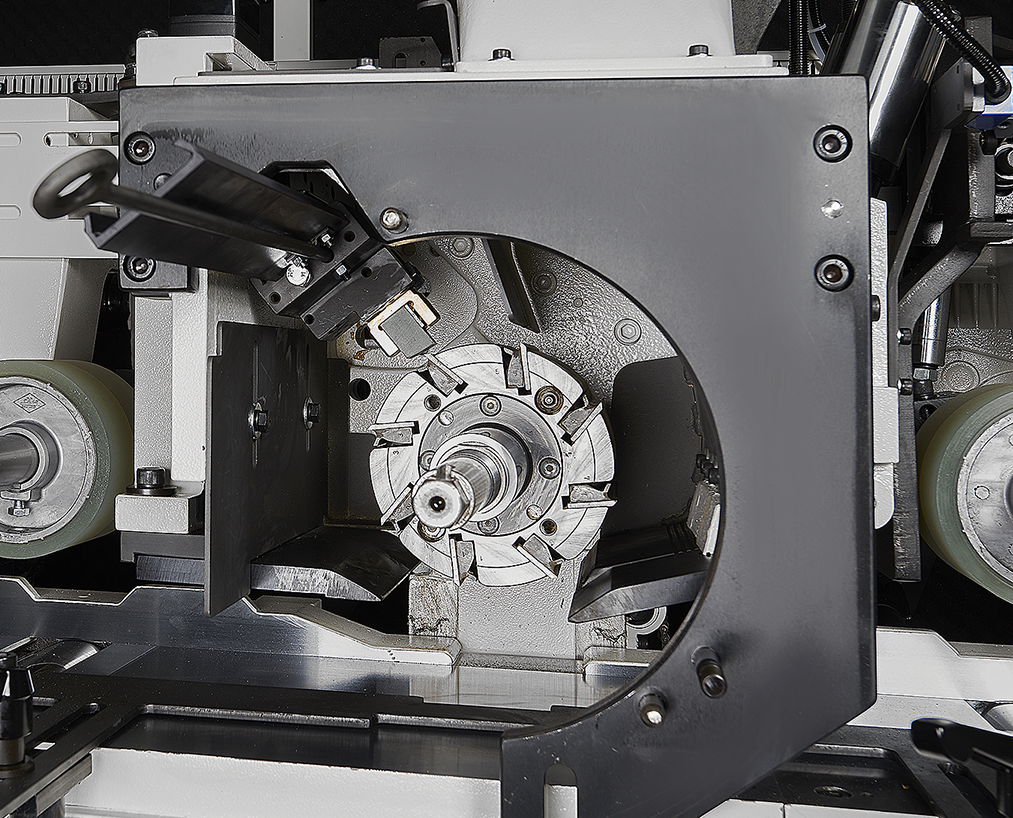

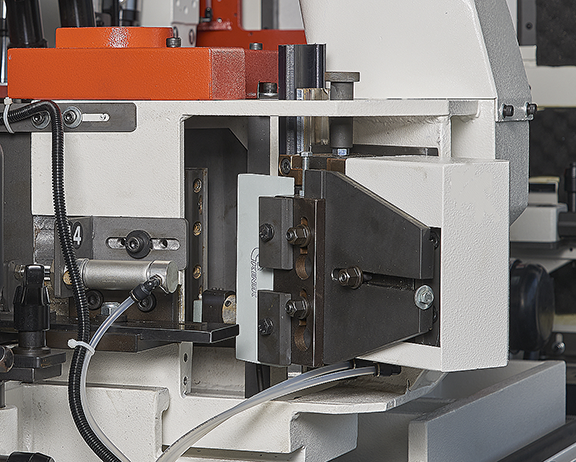

The dynamically balanced spindle with hydraulic outboard bearing support, means maximum stability during cutting is guaranteed. With the optional straight jointer and profile jointer devices combined with computerized automatic position control which greatly upgrades operation convenience and cutting stability.

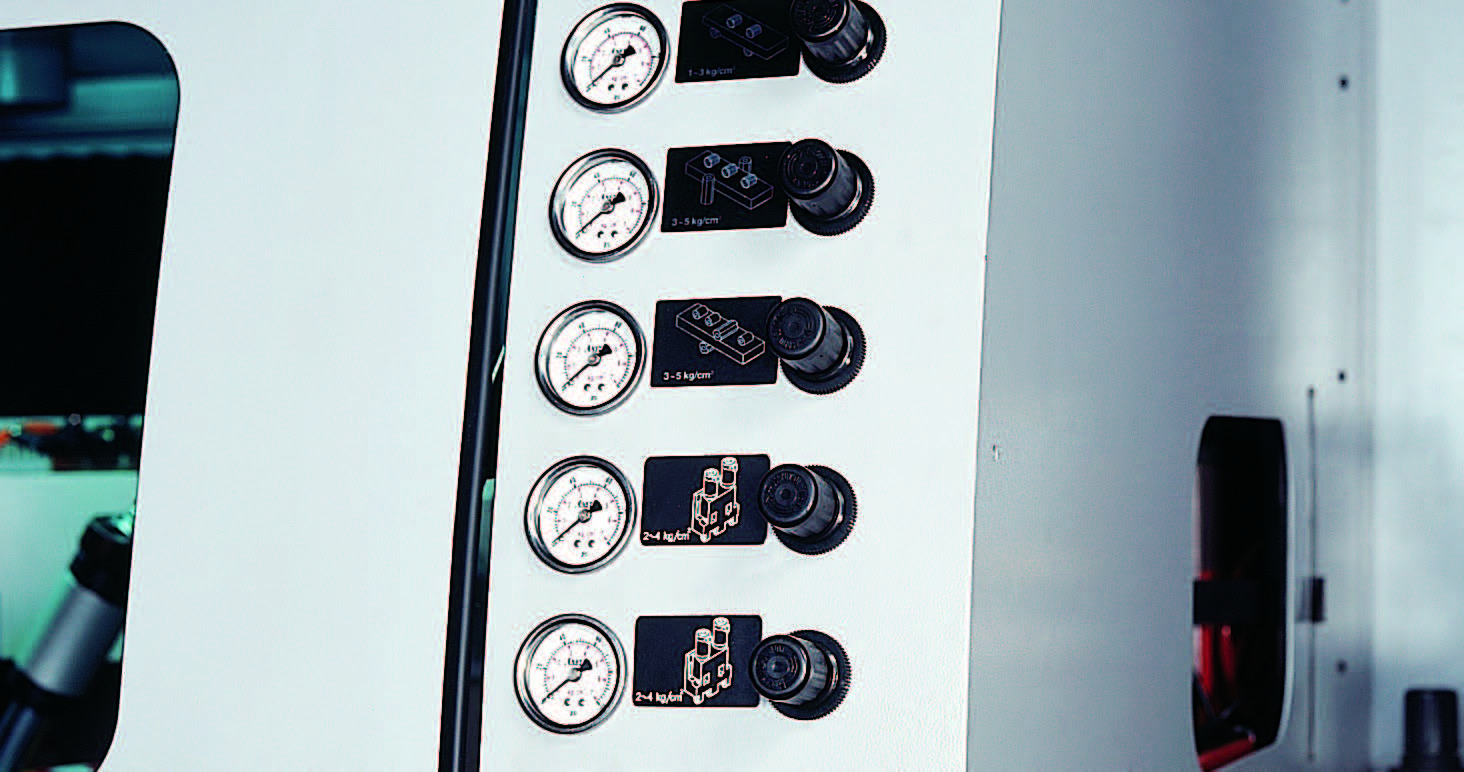

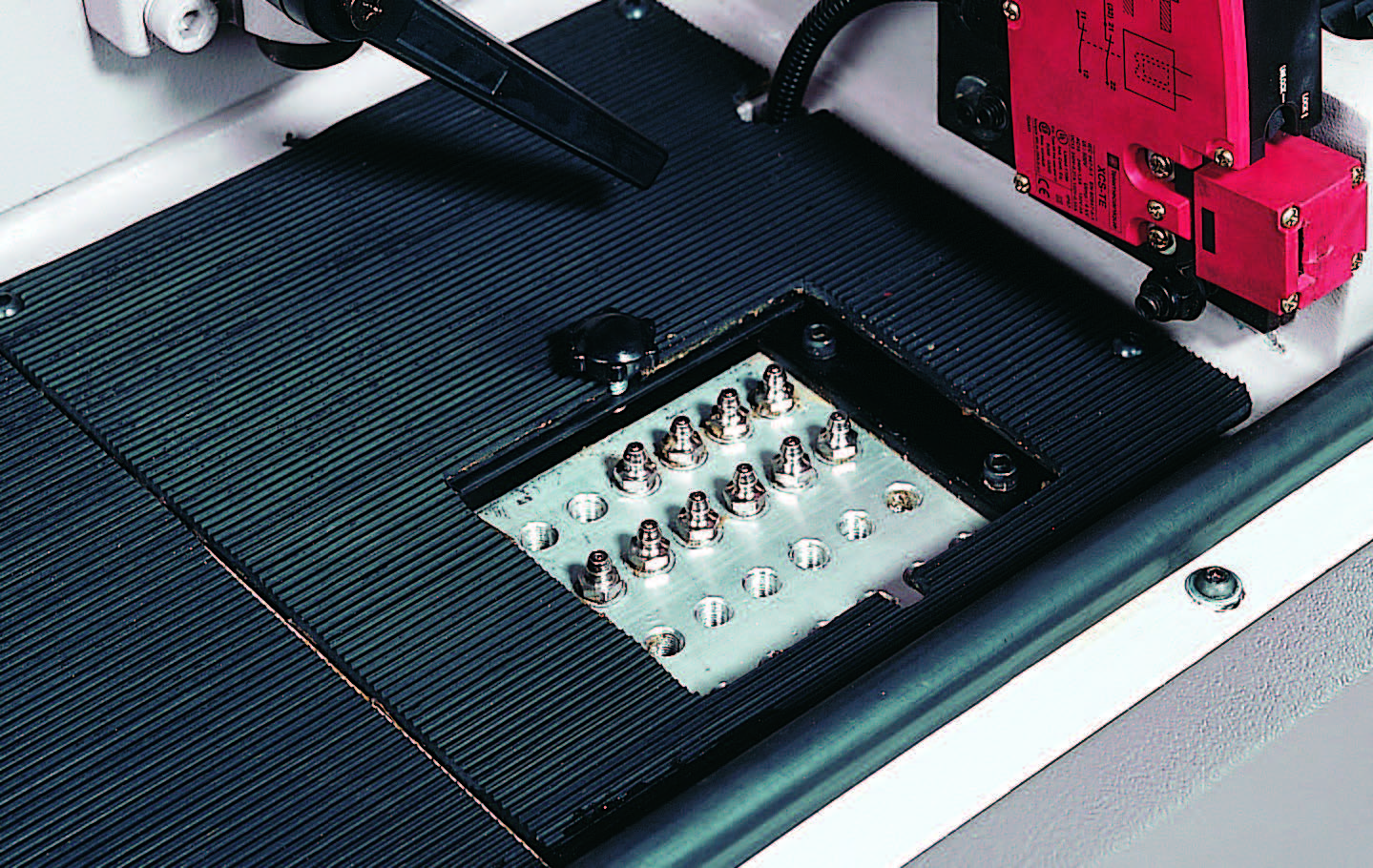

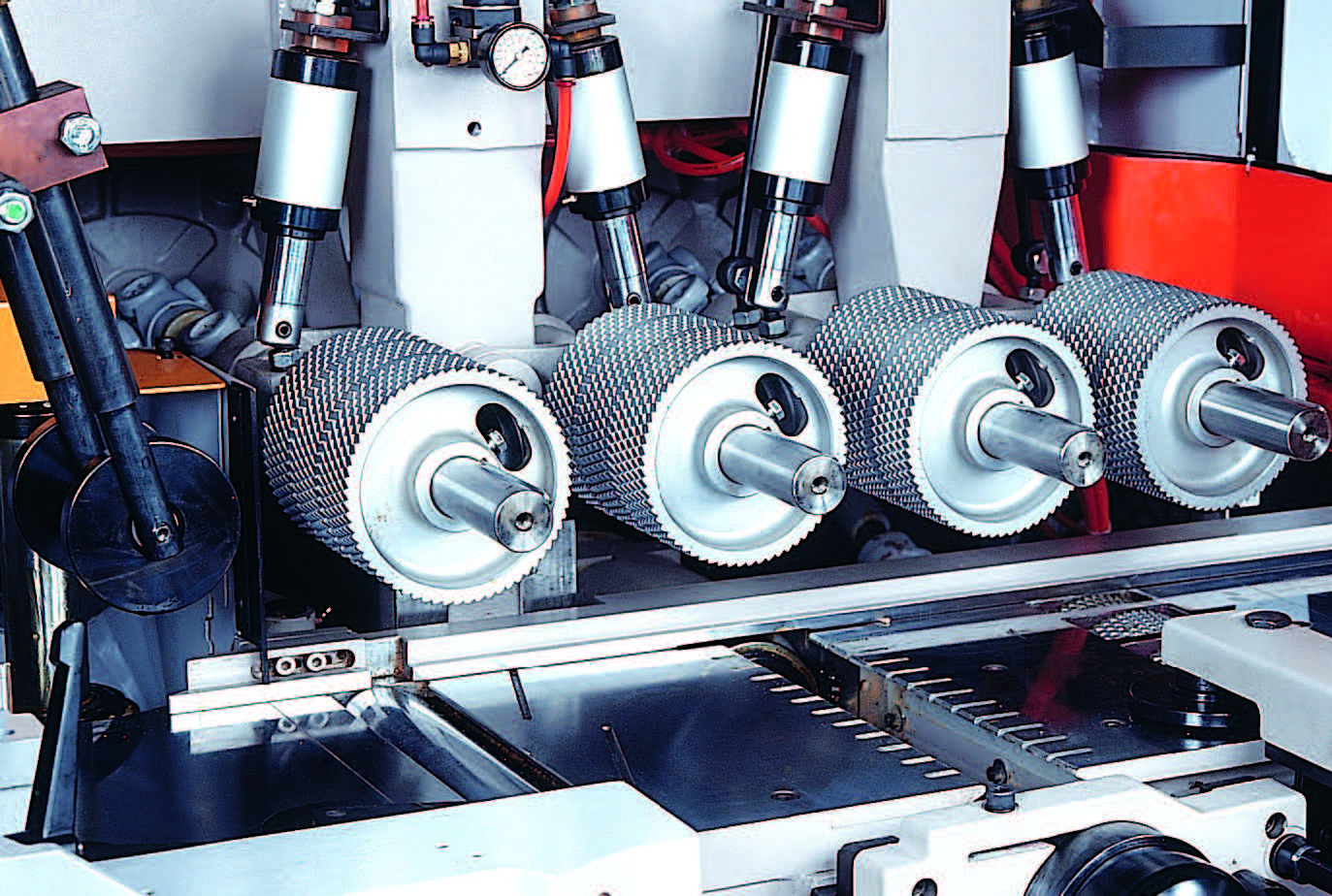

Another optional 60 or 80 m/min high speed feed allows for achieving higher production output. Pneumatic pressure roller with multiple-stage control ensures consistent pressure throughout the entire feed system. For extra wide cutting problems, the GAU JING GL series always provides the best solution.

OUTSTANDING FEATURES:

OPTIONAL:

SPECIFICATIONS

| MODEL | GL-630 | GL-730 | GL-730A | GL-830 | GL-930 |

| CAPACITY | |||||

| Planing width | 10-300MM | 10-300MM | 10-300MM | 10-300MM | 10-300MM |

| Planing thickness | 7-160MM | 7-160MM | 7-160MM | 7-160MM | 7-160MM |

| Feeding speed (Inverter) | 6-40M/MIN | 6-40M/MIN | 6-40M/MIN | 6-40M/MIN | 6-40M/MIN |

| Min. working length | 230MM | 230MM | 230MM | 230MM | 230MM |

| SPINDLE | |||||

| Spindle speed | 6000RPM | 6000RPM | 6000RPM | 6000RPM | 6000RPM |

| Spindle diameter | Φ50MM | Φ50MM | Φ50MM | Φ50MM | Φ50MM |

| Vertical spindle adjustment (axial) | 60MM | 60MM | 60MM | 60MM | 60MM |

| Horizontal spindle adjustment (axial) | 20MM | 20MM | 20MM | 20MM | 20MM |

| CUTTER DIAMETER | |||||

| 1st bottom spindle | Φ125-160MM | Φ125-160MM | Φ125-160MM | Φ125-160MM | Φ125-160MM |

| Vertical spindle | Φ100-200MM | Φ100-200MM | Φ100-200MM | Φ100-200MM | Φ100-200MM |

| Top spindle | Φ100-200MM | Φ100-200MM | Φ100-200MM | Φ100-200MM | Φ100-200MM |

| Last bottom spindle | Φ100-250MM | Φ100-250MM | Φ100-250MM | Φ100-250MM | Φ100-250MM |

| MOTOR | |||||

| 1st bottom spindle | 15HP | 15HP | 15HP | 15HP | 15HP |

| Vertical spindle | 10HP | 10HP | 10HP | 10HP | 10HP |

| Top spindle | 15HP | 15HP | 15HP | 15HP | 15HP |

| Last bottom spindle | 15HP | 15HP | 15HP | 15HP | 15HP |

| Feeding motor (Inverter) | 10HP | 10HP | 10HP | 15HP | 15HP |

| Elevation motor | 1HP | 1HP | 1HP | 1HP | 1HP |

| OTHERS | |||||

| Table adjustment | 12MM | 12MM | 12MM | 12MM | 12MM |

| Infeed table length | 1800MM | 1800MM | 1800MM | 1800MM | 1800MM |

| Feeding roller diameter | Φ140MM | Φ140MM | Φ140MM | Φ140MM | Φ140MM |

| Feeding roller width | 3x50MM | 3x50MM | 3x50MM | 3x50MM | 3x50MM |

| Machine dimensions (LxWxH) | 4700x2020x1840MM | 4900x2020x1840MM | 5260x2020x1840MM | 5600x2020x1840MM | 5600x2020x1840MM |

| Packing dimensions (LxWxH) | 4900x2280x2120MM | 5100x2280x2120MM | 5460x2280x2120MM | 5800x2280x2120MM | 5800x2280x2120MM |

| Net weight | 6000KGS | 6600KGS | 7300KGS | 7900KGS | 8500KGS |

| *SPECIFICATIONS AND DESIGN CHARACTERISTICS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE. | |||||