Feed speed: 6~40/60/80/100/120 m/min

Planing width: 20-450mm

Planing thickness: 7-160mm

GAU JING’s newest developments with heavy-duty and wide planning moulder - the GL-45 series, just launched! Now you have moulders that can handle the toughest working jobs without a doubt.

The GL-45 series moulder is designed to meet your expectations on heavy duty cutting, upgrading 450mm wide cutting and high productivity. This moulder makes it easy for working on construction applications such as beams, pillars, and wide boards.

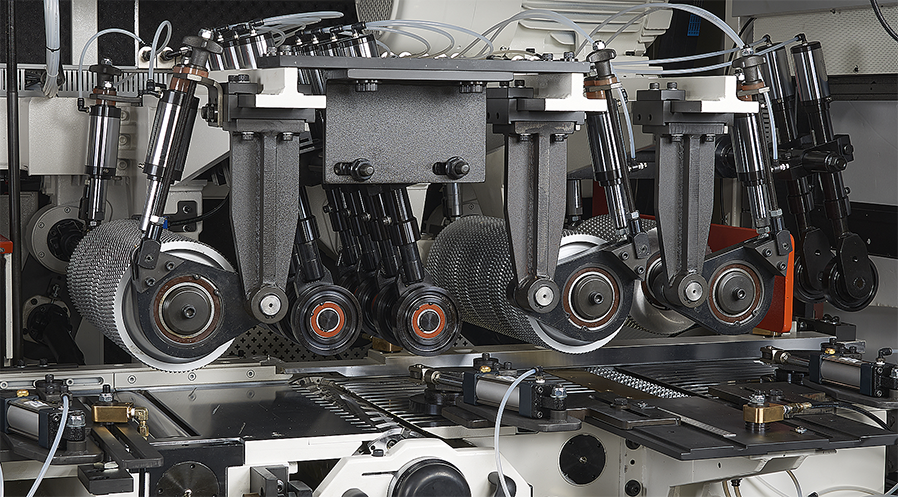

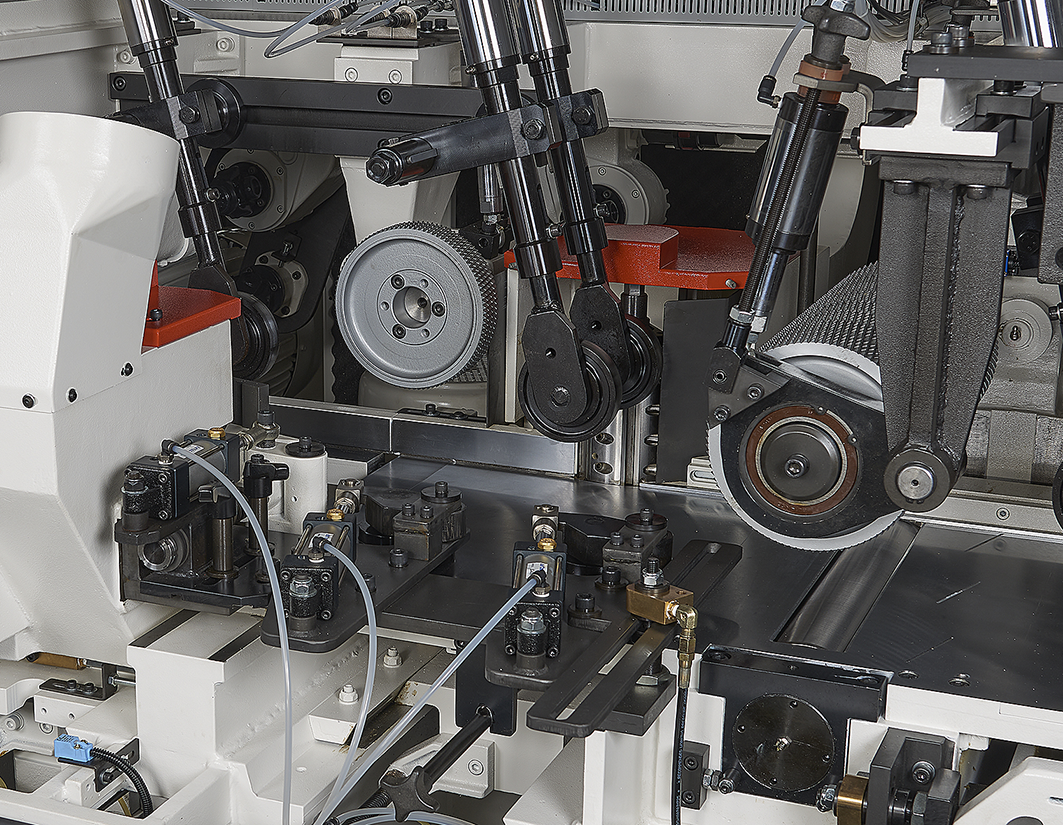

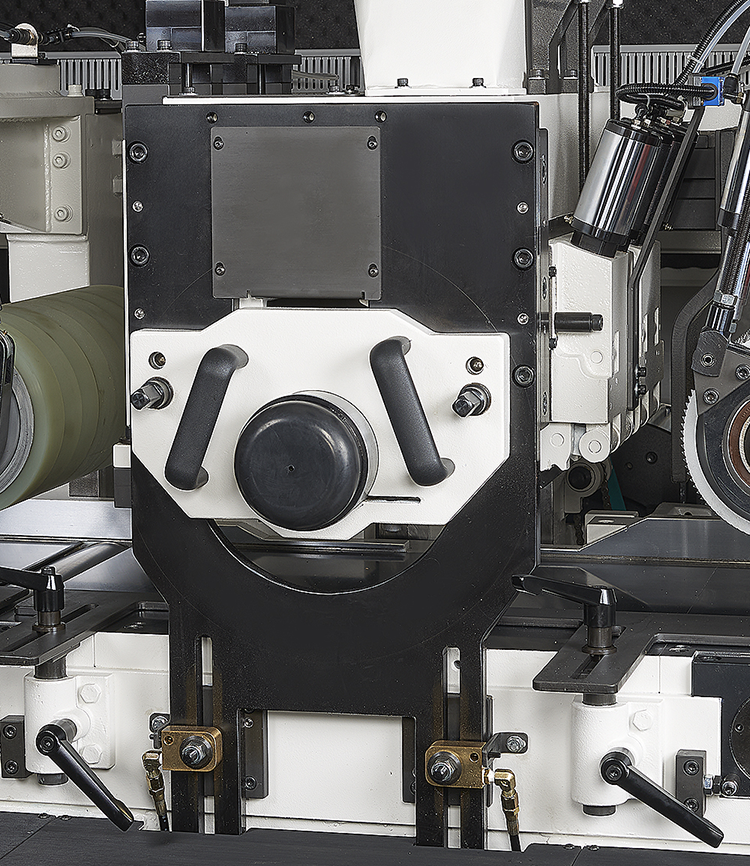

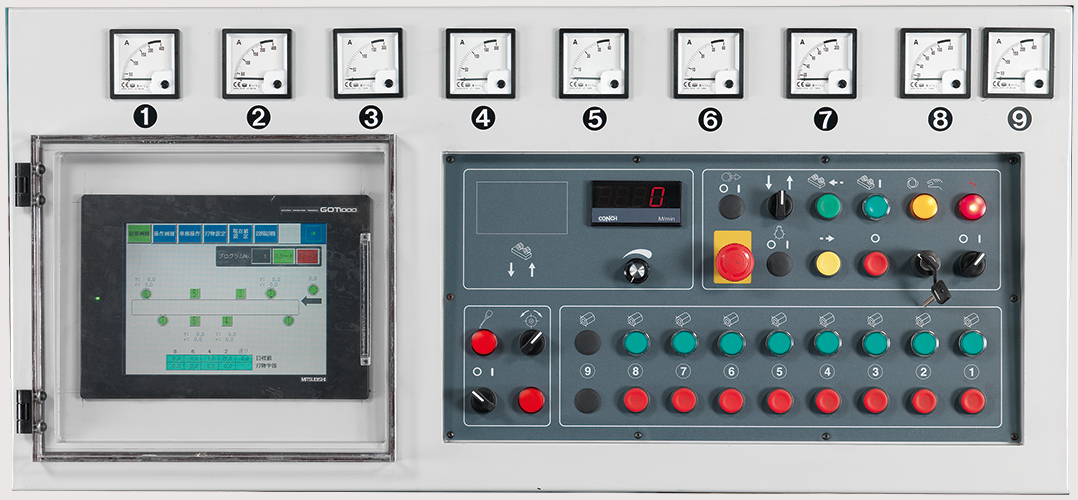

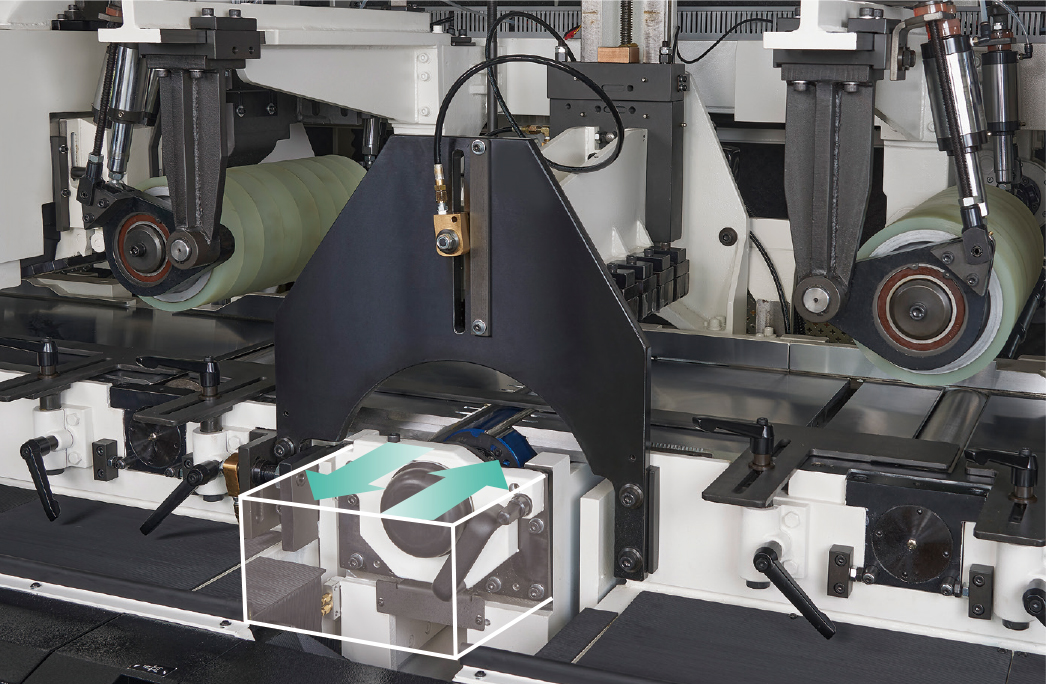

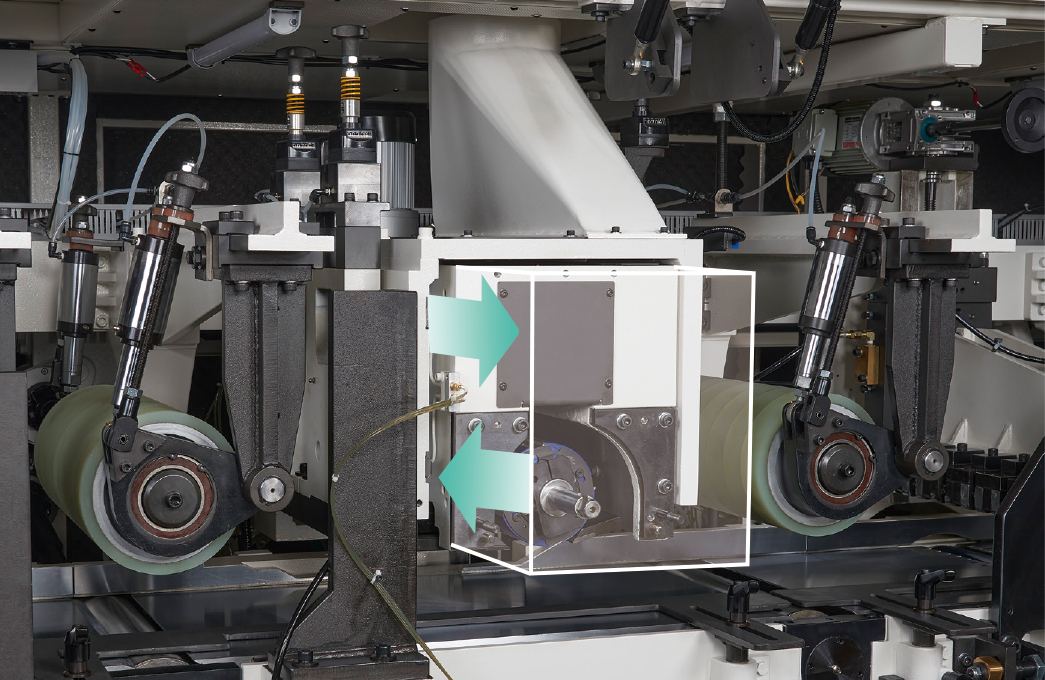

The powerful rigid structure of the machine with high speed accurate spindles and 450mm wide feeding rollers with hydraulic outboard bearing support, ensures maximum stability during cutting. With optional straight knife jointer and profile knife jointer devices combined with ATS system automatic position controller to help you increase production capacity and cutting stability.

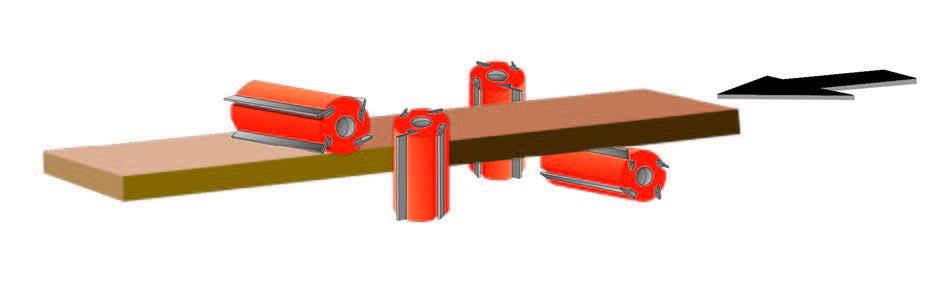

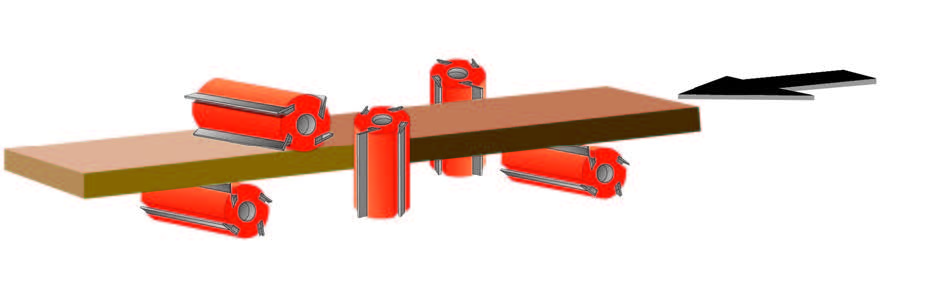

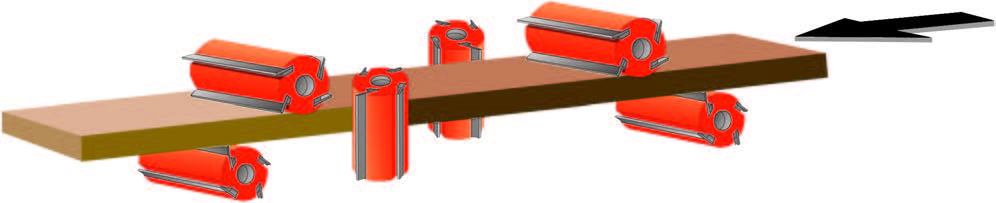

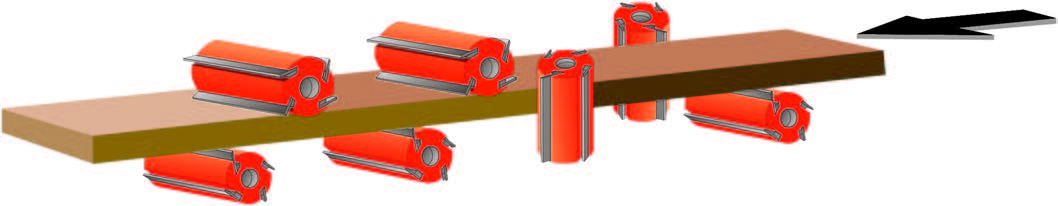

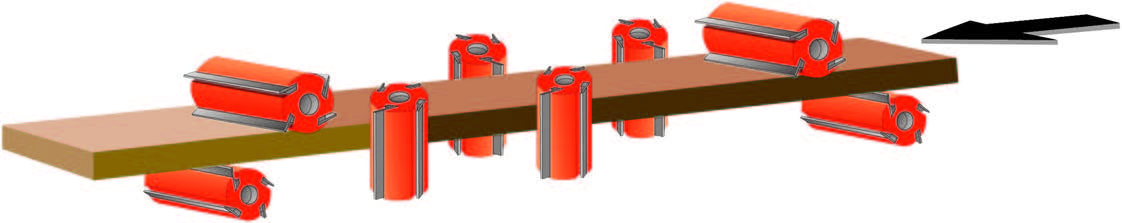

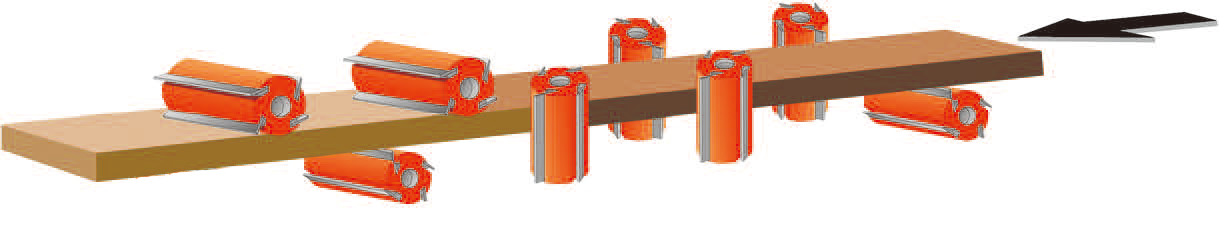

Spindle arrangement from 4 to 8 spindles cooperate with feeding speed from 40m/min, 60m/min, 80m/min, 100m/min up to 120m/min to meet various working applications.

OPTIONAL:

SPECIFICATIONS